A significant problem compressed air systems face is the accumulation of unwanted moisture generated during the compression process. Water vapor precipitated within the compressed system can cause damage to its components resulting in costly downtime. Also, most industrial processes that use compressed air cannot manufacture high-quality products if the process air is not properly dried.

The use of aftercoolers can help reduce the moisture in your process air. This article will focus on how air compressor air coolers function within an industrial air-drying layout and outline the air cooler types available.

Please navigate to our equipment rental category if you need to rent an air compressor aftercooler instead.

What Is an Aftercooler for Air Compressors?

Every air compression process generates some amount of heat referred to as the heat-of-compression and the temperature values vary differ between compressor types. An air compressor aftercooler device is a device that acts as a heat exchanger removing the heat of compression from a stream of compressed air.

The intent in this action is to reduce the temperature of the air stream. Taking the system temperature below the dew point temperature of compressed air allows suspended water vapor to condense and be eliminated. This results in a drier, high-quality air more suitable to your industrial applications.

Air-Cooled vs. Water-Cooled Air Compressor Aftercoolers

Compressor aftercoolers are typically air-cooled or water-cooled variants. The choice of aftercooler for your system depends on various factors including floor space, siting considerations and the availability of adequate water supply.

Regardless of type, approximately 80% of moisture is suspended in compressed air by both pneumatic aftercoolers and their water-powered counterparts.

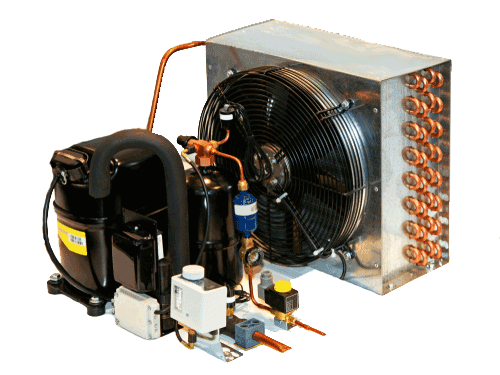

Air-Cooled Aftercooler

An air to air aftercooler uses environmental air to achieve its compressed air cooling effect. The typical setup is a series of coiled tubes through which the heated compressed air is channeled. Ambient air is pulled from the external environment by motor-driven fans and forced over the coils to cool the air within the aftercooler’s tubing.

Once the compressed air has cooled sufficiently the suspended moisture condenses and can be collected by a dedicated basin while dry compressed air is channeled to a separate outlet.

Water-Cooled Aftercooler

Different variants of water-cooled aftercoolers are available for compressed air drying processes. A common water-cooled aftercooler is the shell and tube version. This heat exchanger type is composed of a network of coiled tubes within a shell casing. While heated compressed air is passed through the tubes in one direction, cool water is channeled through the surrounding shell eliminating the heat from the process. As cooling is achieved, suspended water is precipitated into the aftercooler coils and is removed by an attached moisture separation unit.

Why Do You Need to Dry Compressed Air?

By convention, the higher the temperature of environmental air, the higher its water vapor content. Compressing this air raises its temperature further (heat of compression) thus increasing its water saturation.

Compressed air with a high content of vaporized water is not ideal for most industrial processes as they mostly require dried air. Apart from their non-suitability for industrial manufacturing, compressed air with high levels of moisture will damage compressor components by causing corrosion and channel blockages.

To avoid an accumulation of damaging moisture, compressed air coolers are incorporated into compressor systems to rid the air excess water.

How to Test Compressed Air

Compressed air testing helps ensure the quality of compressed industrial air meets minimum international standards. At present, the ISO 8573 compressed air guidelines are employed in several countries globally including India, the US, and the UK. These guidelines involve the use of microscopy, lasers, oil and water vapor sampling techniques to standardize industrial compressed air manufacturing processes.

NiGen Has Compressed Air Coolers for Your Process Air Applications

At NiGen we prioritize the delivery of the best quality compressed air supplies to all our clients. In addition to our industrial air compressors, we also provide air compressor aftercoolers, air dryers, industrial nitrogen generators, and industrial generators to help optimize every aspect of your production process.

Contact us online today to learn more about how we can help with your compressed air needs.