Industrial processes, ranging from oil and gas recovery to food and beverage processing, utilize compressed air at various stages of production. In most cases, operators of industrial plants that use dry air install on-site air compression units with integrated air-drying systems.

Please navigate to our equipment rental category if you need to rent high-pressure booster compressors instead.

While this approach might provide cost-saving benefits for some industries, it is not always the ideal method for fulfilling industrial compressed air needs. The use of an air pressure booster enables the production of compressed plant air precisely where it’s needed, thereby improving process efficiency and reducing operating costs.

What is a High-Pressure Booster Compressor?

An air pressure booster system is a device that optimizes pre-compressed air circulating within an industrial system. Air from a low-pressure compressor can be multiplied by a booster to yield compressed air at significantly higher pressures. A standard air pressure booster pump can raise the pressure of circulating pre-compressed air as much as 10 times its original value.

Applications of an Air Pressure Booster

Pressurized air boosters can be used to optimize air supply in industrial processes that require compressed air. Typical booster air compressor applications include:

- PET bottle production

- Pressure maintenance in die cushions

- Actuated braking systems

- Testing industrial conduit and pipeline pressures

- Gas injection enhanced oil recovery

- Improving maximum torque in small air tools

- Optimizing high-pressure tires

- Engine starter systems

- Laser cutting operations where consistent high pressure and discharge pressure are critical

Several of the applications above are further outlined below.

Testing Industrial Pipeline Pressures

Highly pressurized air supplied by an air booster device can be used to conduct industrial pipeline inspections effectively. These pipeline maintenance services typically involve passing a stream of compressed air through a pipeline and removing the gas via relief valves. An unaccounted loss in pressure indicates a potential leak, and this can guide maintenance efforts. Gas boosters may also be used in these operations for enhanced pressure testing performance.

Contact NiGen today about our pipeline cleaning services!

PET Bottle Production

Rapid and efficient production of polyethylene terephthalate (PET) bottles requires a steady stream of highly compressed air. Booster compressors can provide plastic mold machines with the necessary air pressure stream to achieve optimal bottle casting.

Enhanced Oil & Gas Recovery Techniques

As oil and gas wells age, the natural formation pressure decreases, resulting in a decline in the output of recovered oil. To improve productivity, oil and gas project operators can introduce compressed air into the oil wells as an enhanced recovery method. Using a high-pressure booster compressor in natural oil and gas recovery will compensate for natural formation pressure losses.

Benefits of NiGen’s Air Pressure Booster Compressor

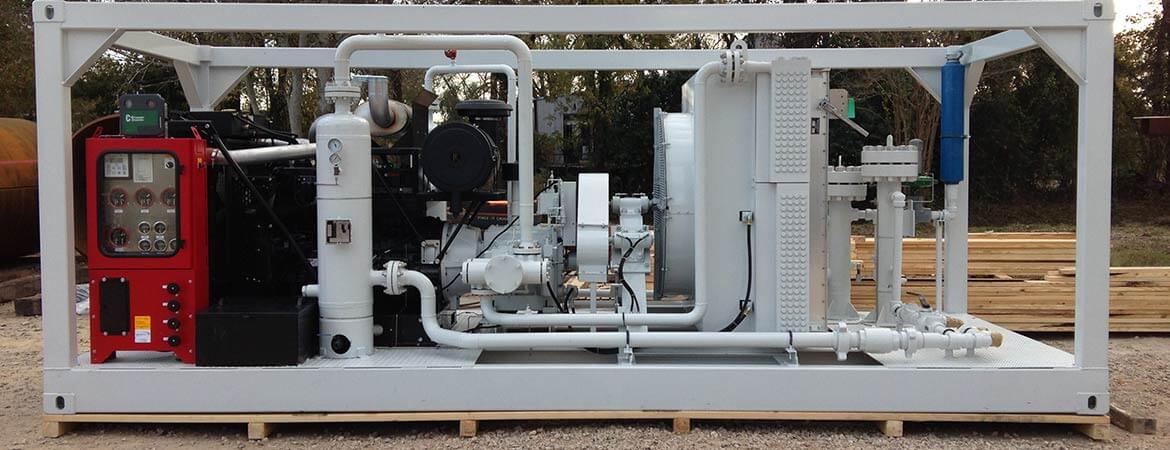

NiGen manufactures high-quality pressure boosters that serve various industries requiring compressed air, including oil and gas, transport pipeline, and food and beverage manufacturing.

Customized Booster Productivity

NiGen’s high-pressure air booster systems are engineered to perform in demanding environments. These units multiply inlet pressure up to 10 times through a three-stage compression process, delivering the discharge pressure required for industrial operations, especially where high-pressure cylinders are used.

Easy Control Interface

NiGen air boosters come preinstalled with easy-to-understand and user-friendly control interfaces. A series of audible alarms and announcements alert operators to impending dangers or machinery damage allowing prompt interventions. Also, information screens provide a complete overview of all operating parameters clearly and concisely.

Serviceability & Safety

Designed for durability, NiGen boosters include automated safety shutdowns, intuitive alarm systems, and are easy to service with support from our certified technicians.

Contact us about our process equipment field services for further help today!

Skid-Mounted

The air pressure boosters manufactured by NiGen include modifications for skid compatibility. This feature allows units to be securely transported from one location to the other and easily operated at the intended production sites.

Frequently Asked Questions

What’s the difference between a high-pressure booster compressor and a regular compressor?

A booster increases the pressure of air that’s already been compressed, while a regular compressor generates compressed air from ambient air. Many operations find adding a booster to a standard compressor results in better performance without major equipment changes.

Can these units be used outdoors or in remote locations?

Yes. NiGen’s skid-mounted booster compressors are designed for mobility and can operate in rugged field environments.

Do I need an air dryer with a booster compressor?

Depending on your application and environmental conditions, using an air dryer can help ensure that moisture does not affect equipment performance or product quality.

How do I know if I need a booster vs. a new compressor system?

If your existing system can’t meet higher pressure requirements but still works efficiently at lower pressure levels, adding a booster is often the smarter and more affordable option.

NiGen Has the Air Pressure Booster System You Need

At NiGen, we prioritize supplying the highest quality compressed air systems to all our clients. We offer high-pressure booster compressor installation and maintenance, as well as a range of industrial equipment, including air compressors, on-site nitrogen generators, air dryers, air coolers, and industrial generators.

Contact us online today to learn more about how we can help with your compressed air needs.