One of the greatest issues facing compressed air systems during the compression process is the buildup of undesired moisture. If industrial process air is not suitably dried, most operations that depend on compressed air will not be able to deliver high-quality products. Water vapor or moisture in the compressed air system can wreak havoc on its individual components, bringing production to a halt. Using an aftercooler can aid in drying your process air– find out how air compressor air coolers work in an industrial air-drying system and the different types available for rental at NiGen.

Please navigate to our equipment purchase category if you need to buy a compressed air aftercooler instead.

What Is an Aftercooler for Air Compressors?

What Is an Aftercooler for Air Compressors?

During the air compression process a small amount of heat is generated, which is known as the “heat-of-compression”. Temperatures will fluctuate depending on the type of compressor. The purpose of an air compressor aftercooler device is to act as a heat exchanger. The aftercooler removes the heat-of-compression from the compressed air stream and reduces the temperature below the dew point temperature of compressed air. The water vapor present in the air stream will then condense and be discarded for a higher-quality, dry air that can properly be used in your industrial operations.

Air-Cooled vs. Water-Cooled Air Compressor Aftercoolers

Most compressor aftercoolers are either air-cooled or water-cooled. Whichever one you choose to rent should revolve around factors such as available floor space, site conditions, and water supply availability. Both pneumatic aftercoolers and water-powered aftercoolers ensure that approximately 80% of moisture will be suspended in the compressed air.

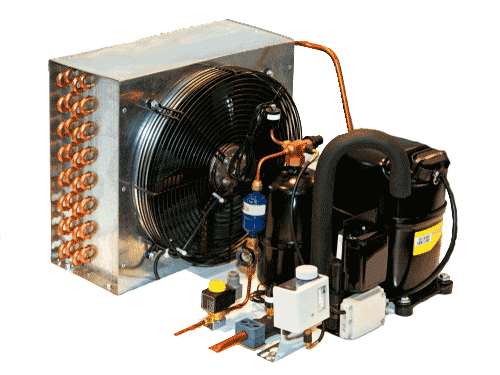

Air-Cooled Aftercooler

Air-to-air aftercoolers use the surrounding air to cool compressed air. First, the compressed air that needs to be cooled is funneled through a series of coiled tubes. Next, external environmental air is forced over the coiled tubes to cool the air inside. After the compressed air has cooled enough, the water vapor that has condensed is funneled into a dedicated basin while the newly cooled and dried compressed air continues along the system.

Water-Cooled Aftercooler

There are several different types of water-cooled aftercoolers for compressed air drying processes available on the market. A typical water-cooled aftercooler is the shell-and-tube aftercooler– this variant is made up of a system of coiled tubes inside a shell casing. Compressed air is forced through these coiled tubes while cool water is simultaneously flowing in the surrounding shell, reducing the temperature and causing suspended moisture to condense. The suspended water then falls into the aftercooler’s coils and into an attached moisture separation unit where it is then discarded.

Why Do You Need to Dry Compressed Air?

Generally, the higher the temperature of the air, the more moisture it will contain. Compressing air increases the heat even more and further extends water saturation levels. Most industrial processes that depend on compressed air require drier air, since moisture is damaging to several components and products. Large amounts of moisture can cause channel blockages and corrosion over time. Compressed air coolers are often integrated into air compressor systems to prevent this and get rid of unwanted water vapor.

Testing Compressed Air

Compressed air testing is a crucial tool in maintaining minimum international standards of compressed industrial air quality. Currently, the ISO 8573 compressed air guidelines are internationally implemented in countries such as the United States, the United Kingdom, and India. They concern the use of lasers, microscopy, and oil and water vapor sampling techniques to standardize the industrial compressed air manufacturing process and other relevant operations.

Compressed Air Cooler Rental vs. Purchase

Renting a compressed air cooler may be a better choice for your business than buying one. Renting will reduce your cost of ownership and lower capital operating costs– especially for smaller companies that benefit from owning fewer assets. Whatever you decide, NiGen has several options available for you to choose from!

NiGen Has Compressed Air Cooler Rentals for Your Process Air Applications

At NiGen, we are committed to delivering the best-quality compressed air equipment to our valued customers. Along with air compressor aftercooler rentals, we can also provide air dryer rentals, industrial nitrogen generators, and industrial generators to help you meet and exceed your specific project’s requirements.

Contact us to find out how we can help with your compressed air needs and receive a compressed air cooler rental quote today!