On-site nitrogen systems from NiGen International generate a dependable and economical supply of nitrogen gas in the quantity and purity necessary for any application. Our container nitrogen generators are manufactured to the highest quality standards, ensuring long operational lifespans with minimal service requirements and maximum energy efficiency.

NiGen International designs and manufactures the following types of nitrogen generation systems:

PSA Nitrogen Generation Systems

PSA (Pressure Swing Adsorption) Systems generate nitrogen by separating it from the oxygen in ordinary air. PSA nitrogen generation systems are a safe and reliable method for generating high purity nitrogen gas on location for laboratories and other industries that require N2 in their applications. They are a cost-effective alternative to delivered gas.

Membrane Nitrogen Generators

Membrane generators force compressed air into a vessel containing a hollow tube surrounded by a polymeric hollow fiber. The hollow fibers selectively permeate oxygen, water vapor, and other impurities out of their sidewalls, allowing nitrogen to flow through the center and emerge as gas.

How NiGen Membrane Nitrogen Generators Work

Our nitrogen membrane technology is an efficient alternative to PSA systems. We use high-selectivity hollow fiber membranes for nitrogen gas separation. These semi-permeable layers are made of flexible, cylindrical filaments with pore sizes from 0.03 to 10 microns.

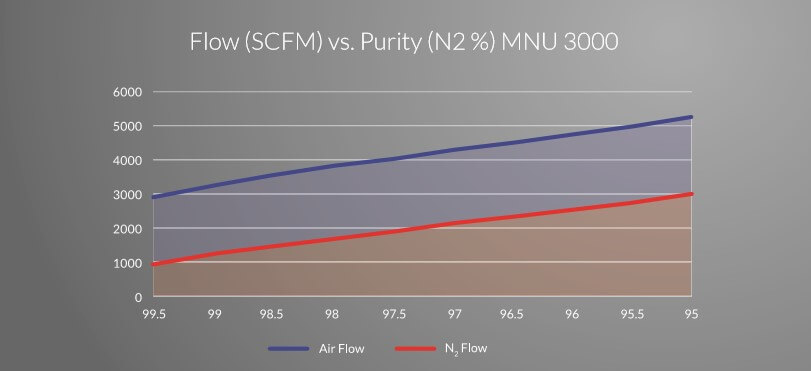

Dry, compressed air is applied over the material to separate nitrogen gas which is housed in a cylindrical vessel. The nitrogen membrane allows N2 to pass through while inhibiting oxygen, inert gases, water vapor, and other impurities. The membrane selectivity is dependent on pore size. Membrane nitrogen gas generators can produce purities up to 99.95%.

These are membrane nitrogen generators mounted on either trailers or skids for portability. We design our mobile nitrogen generators to customer specifications, maximizing nitrogen generation within a predefined footprint.

4 Benefits of Onsite Nitrogen Generators

On-site nitrogen generation has proven to be one of the most reliable ways to generate high-purity nitrogen. Below are some of the benefits of using this option:

Combine our industrial nitrogen gas generators with our mobile air compressors and twin tower desiccant dryers for the best quality process air that will help prevent system decay and costly downtime.

Nitrogen Container Systems

These nitrogen generation systems are designed to fit a 10-, 20-, or 40-foot steel ISO container or similar structure that can be easily transported on a truck. When the nitrogen container unit reaches the end-user’s facility, it only requires an electrical hookup to begin generating nitrogen on-site. In addition to the cost-savings, ease of implementation is one of the main benefits of our on-site nitrogen generators.

On-Site Container Nitrogen Generator Details

Our on-site generation systems are designed for portability and reliability. Our process equipment field services are second to none, and we go to every effort to make sure your equipment doesn’t slow down your operations.

- 99.9 to 92% Nitrogen Purity

- Automated PLC Control System

- HMI Touch Screen

- Electronic and Mechanical Monitoring System

- High Efficiency Membrane Technology

- Non Depleting Oxygen Sensor

- Containerized

- Protective Shutdown Controls

- Dew Points <-70° F

- Zero-Loss Condensate Auto Drains

- Low-Voltage 24VDC Power Requirement (Eliminates 3-Phase External Generator Need)

Easy Nitrogen Generator Installation

Because of the modular design of our membrane nitrogen generators, introducing nitrogen gas into your O&G process is easy. Contact a member of our technical team to learn how easy nitrogen generator installation is with our external container hookups.

We also have certified technicians who can service your compressor and nitrogen gas generators.

Contact us today to find out more.