How to Improve Air Compressor Efficiency & Lower Energy Costs

Compressed air is one of the more expensive utilities in an industrial facility...and it is also one of ...

Atmospheric Vent Silencers for Reducing Pipeline Noise

Noise pollution from industrial activities is a major concern for operators and environmental regulatory agencies alike. In the ...

Pipeline Maintenance Planning: Steps for Safe Purging & Inerting

Pipeline maintenance planning often gets simplified into a checklist. But in practice, purging and inerting work only when ...

Industrial Guide: What Size Air Compressor Do I Need?

In practice, air compressor sizing comes down to air demand, pressure requirements, duty cycle, and how forgiving the ...

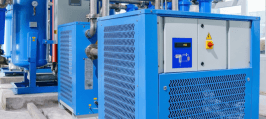

Refrigerated Air Dryer for Air Compressor Systems: How They Work

Compressed air is a vital utility in various industries, serving as a power source for tools, equipment, and ...

What is Nitrogen Used For? Top Industrial Uses of Nitrogen Gas

As an inert and stable gas, nitrogen plays a key role in many industrial processes that depend on ...

Pipeline Leak Detection & Testing: Methods & Best Practices

Leak detection is not fancy work, but it is necessary. Even a small unnoticed leak can cause product ...

Pipeline Inspection Checklist for Oil & Gas Operators

Pipeline inspection is one of those jobs that never ends in oil and gas operations. The work keeps ...

Industrial Pipeline Cleaning: Services, Equipment, and Maintenance Timing

Like any other industrial equipment, pipelines require routine maintenance to maintain optimal functionality. With exposure to both internal ...

How to Pig a Pipeline – Gas Pipeline Pigging Procedure

Accumulation of debris, grease, corrosion, and fractures in gas pipelines poses a significant threat to flow integrity, potentially ...