How to Pig a Pipeline – Gas Pipeline Pigging Procedure

Accumulation of debris, grease, corrosion, and fractures in gas pipelines poses a significant threat to flow integrity — potentially leading to accidents. Fortunately, a specialized tool called a “pipeline pig” can help prevent these issues and maintain optimal flow assurance. Let’s discuss the pipeline pigging procedure, various types of gas line pigs, and their common applications.

What is a Pipeline Pig?

Pipeline “pigs,” short for “pipeline intervention gadgets,” are devices used to clean or inspect pipelines in upstream, midstream, and downstream O&G operations. The name may have originated from the “squealing” sound of early pig models (made of straw, wire, or leather) produced while traveling through pipelines.

What Is Pigging in Oil and Gas Pipelines?

Pigging in the oil and gas industry is a form of flow assurance where pipeline pigs purge, clean, and inspect pipelines to keep them running smoothly. Since the operation is hazardous, pigging must only be carried out by experienced professionals.

Purpose of Pipeline Pigging

The following are some justifications for pigging gas pipelines:

- Cleaning: to remove debris, scale, and contaminants from the pipeline walls, preventing buildup that could impede flow and lead to corrosion.

- Inspection: to assess the internal condition of the pipeline, identifying defects, irregularities, and potential issues to proactively address maintenance needs.

- Efficiency Optimization: to enhance the overall efficiency of the pipeline by reducing friction, optimizing flow, and minimizing the energy required for material transportation.

How Does Pipeline Pigging Work?

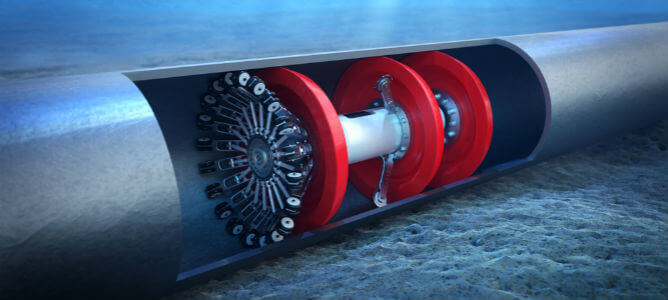

Pipeline pigging involves using “pigs” to clean, inspect, or perform pipeline maintenance tasks. The typical pigging system consists of a pig, a launcher, and a receiver, collectively known as the “pig trap.” The pig is a cylindrical device that travels the length of a pipeline by being pulled by a string or using the force of a fluid flowing through the line.

The pig launcher releases the pig from one end of the pipeline (launcher station), and the receiver retrieves it at the other end (receiver station). Pipeline pigging is a potentially hazardous procedure that should only be carried out by competent professionals.

Common Types of Pipeline Pigs

In the oil and gas industry, various types of pipeline pigs are utilized for different purposes in pipeline maintenance and operation. Here are some common types:

Utility Pigs

Utility pigs are used for cleaning, dewatering, and sealing gas pipelines. To flush a gas line, a utility pig sweeps through the internal section, scraping off debris and semi-solids that obstruct or limit the flow of hydrocarbons.

When used for dewatering or sealing, the pig provides air and moisture-tight coupling to flush liquids from the line or separate different in-line media.

Utility pigs can be further divided into the following types:

- Mandrel Pigs: Mandrel pigs have a solid body with a central mandrel, providing stability and control during pipeline cleaning and inspection. They are often used for removing debris and ensuring the pipeline’s integrity.

- Solid Cast Pigs: Solid cast pigs have a compact, one-piece design without moving components. They are robust and efficient for cleaning applications, where a simple, durable design is preferred to navigate through the pipeline effectively.

- Foam Pigs: Foam pigs are made of foam materials and are lightweight. They are suitable for light cleaning and batching applications, offering a gentle yet effective way to navigate pipelines in less abrasive environments.

- Spherical Pigs: Spherical pigs are round and often used for general cleaning and batching. Their design allows them to move quickly through the pipeline, efficiently cleaning and separating different product batches.

Gel Pigs

Gel pigs consist of chemical substances such as rigid polymers and high-viscosity gels. They are typically used during pipeline commissioning or maintenance. They are the ideal option for so-called “unpiggable” lines – pipelines containing internal valves, sharp bends, or special structures that could result in a stuck pig.

Unlike other pig types, gel pigs do not require a launcher and receiver system. Gel pigs are often used alongside different types of pigs to improve the efficiency and prevent deterioration of the primary pig components. They can also help to retrieve a pig stuck in a pipeline.

Inspection Pigs

Inspection pigs or “smart pigs” are used to inspect internal sections of gas pipelines ahead of remedial activities. They contain electronic components such as ultrasonic sensors, RF modules, and pig gauge plates, and can measure parameters such as diameter, curvature, thickness, pressure, metal loss, and temperature. Newer inspection pigs can detect issues in pipelines, such as leaks, cracks, wax deposition, and corrosion, with a high degree of accuracy.

Specialty Pigs

These types of pigs, also called “plugs,” seal off entire sections of pipelines while remedial activities are being carried out. Specialty pigs are used by pipeline maintenance service companies for pipeline cleaning without completely restricting the flow of fluids through them.

Discover NiGen’s Pipeline Pigging Services

Are you in need of pipeline-pigging solutions? NiGen provides pipeline decommissioning and commissioning services, including pipeline pigging operations for several petrochemical industries. Our highly trained technicians provide expert advice on choosing suitable pipeline pigs for any operation.

Contact us online today to learn more about our services or request a quote.