How to Pig a Pipeline – Gas Pipeline Pigging Procedure

Accumulation of debris, grease, corrosion, and fractures in gas pipelines poses a significant threat to flow integrity, potentially leading to accidents. Fortunately, a specialized tool called a “pipeline pig” can help prevent these issues and maintain optimal flow assurance.

What is a Pipeline Pig?

Pipeline “pigs,” short for “pipeline intervention gadgets,” are devices used to clean or inspect pipelines in upstream, midstream, and downstream O&G operations. The name may have originated from the “squealing” sound of early pig models (made of straw, wire, or leather) produced while traveling through pipelines.

What is Pigging in Oil and Gas Pipelines?

The pigging process refers to the insertion, propulsion, and retrieval of pigs through pressurized pipelines. This process is used to maintain flow efficiency, identify defects, remove buildup, and separate products in oil pipeline and natural gas systems. Pigging operations are executed using pigging systems that include a pig launcher and pig receiver (collectively referred to as a pig trap). These systems are designed per ASME pipeline standards. Handling pressurized systems and high-velocity projectiles requires qualified personnel and strict adherence to safety protocols.

Purpose of Pipeline Pigging

The following are some justifications for pigging gas pipelines:

- Mechanical Cleaning: Removal of accumulated solids, corrosion scale, paraffin, and biofilm using cleaning pigs.

- Geometry Inspection: Internal gauging to detect ovality, dents, or deformation.

- Intelligent Inspection: Use of intelligent pigs or smart pigs equipped with MFL, UT, or EMAT technology.

- Displacement and Separation: Use of batching pigs to separate product batches or displace liquids.

- Dewatering: Removal of hydrostatic test water or condensed moisture in gas systems.

How Does Pipeline Pigging Work?

A typical pipeline pigging system includes:

- Pig Launcher: Pressurized vessel where the pig is inserted and propelled into the line.

- Pig Receiver: Trap located at the discharge end to collect the pig.

- Pig Trap Assemblies: Includes closures, kicker lines, vent and drain valves.

- Pig Signalers: Devices mounted along the pipeline to detect pig passage.

Propulsion is achieved via differential pressure created by the process fluid (natural gas, oil, or carbon dioxide). Sequential valve actuation and pressure control are required during pig launch and retrieval.

Common Types of Pipeline Pigs

In the oil and gas industry, various types of pipeline pigs are utilized for different purposes in pipeline maintenance and operation. Here are some common types:

Utility Pigs

Utility pigs are used for cleaning, dewatering, and sealing gas pipelines. To flush a gas line, a utility pig sweeps through the internal section, scraping off debris and semi-solids that obstruct or limit the flow of hydrocarbons.

When used for dewatering or sealing, the pig provides air and moisture-tight coupling to flush liquids from the line or separate different in-line media.

Utility pigs can be further divided into the following types:

- Mandrel Pigs: Steel bodies with attached cups, discs, or brushes.

- Solid Cast Pigs: Polyurethane pigs molded without internal mandrels.

- Foam Pigs (Poly Pigs): Open-cell or closed-cell polyurethane foam; used in drying, product removal, or low-pressure applications.

- Spherical Pigs: Hollow or solid balls for basic liquid removal or separation.

Gel Pigs

Gel pigs consist of chemical substances such as rigid polymers and high-viscosity gels. They are typically used during pipeline commissioning or maintenance. They are the ideal option for so-called “unpiggable” lines – pipelines containing internal valves, sharp bends, or special structures that could result in a stuck pig.

Unlike other pig types, gel pigs do not require a launcher and receiver system. Gel pigs are often used alongside different types of pigs to improve the efficiency and prevent deterioration of the primary pig components. They can also help to retrieve a pig stuck in a pipeline.

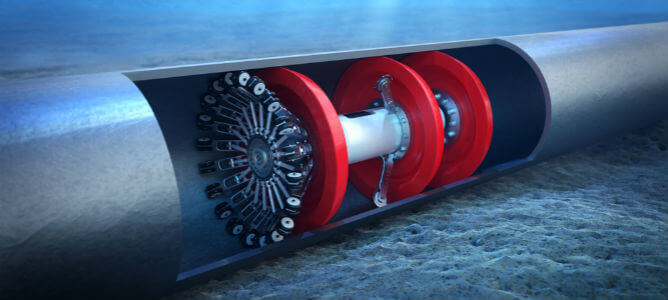

Inspection Pigs (Smart Pigs / Intelligent Pigs)

Inspection pigs or “smart pigs” are used to inspect internal sections of gas pipelines ahead of remedial activities. They contain electronic components such as ultrasonic sensors, RF modules, and pig gauge plates, and can measure parameters such as diameter, curvature, thickness, pressure, metal loss, and temperature. Newer inspection pigs can detect issues in pipelines, such as leaks, cracks, wax deposition, and corrosion, with a high degree of accuracy.

Specialty Pigs

These types of pigs, also called “plugs,” seal off entire sections of pipelines while remedial activities are being carried out. Specialty pigs are used by pipeline maintenance service companies for pipeline cleaning without completely restricting the flow of fluids through them.

Pipeline Pigging Process: Launch to Retrieval

- Preparation

- Select pig based on function and line conditions

- Verify trap seals, closures, signalers, and pressure ratings

- Confirm pigging fluid and flow conditions

- Launch Sequence

- Isolate and depressurize pig trap

- Insert pig into launcher

- Close trap, vent air, equalize pressure

- Open kicker valve to initiate pig movement

- In-Line Travel

- Monitor pig location using pig signalers

- Adjust system pressure and flow rate to maintain velocity (target: 3-7 ft/s)

- Reception

- Detect pig at pig receiver

- Isolate trap, depressurize, drain

- Open closure and remove pig

Pig Tracking Methods and Tools

Tracking pigs is an important part of pigging operations, especially in natural gas pipelines.

Magnetic pig signalers detect changes in magnetic flux as a pig passes by. These are commonly installed along above-ground pipe segments and confirm pig movement in real time.

Acoustic sensors detect the noise or vibration of a pig moving inside the pipeline. These are useful when magnetic detection is limited by pipeline geometry or interference, such as in pigging systems that share rights-of-way or operate in close proximity.

RF transmitters can be embedded in pigs to send signals to receivers. This method is used in buried or subsea pipelines and requires manual surface scanning or fixed receiver stations. RF confirmation is often used when a pig reaches the pig receiver or pig catcher.

For long-distance pipelines, some systems use GPS time synchronization linked to SCADA. This provides a full timeline of pig movement across multiple points in the pipeline network.

Data Output from Smart Pigging and Post-Run Analysis

After a smart pig run, data is downloaded from internal storage or captured via telemetry. Smart pigs, acting as pipeline inspection gauges, collect detailed pipeline integrity data. Reports include:

- Wall loss percentages and affected pipe locations

- Crack lengths and orientation from UT or EMAT tools

- Dents and out-of-round sections from caliper tools

- GPS-based position maps linked to pipeline markers

Pipeline operators use software to process this data, check for problems, and compare results with previous maintenance operations. This supports pipeline integrity planning, especially in natural gas and carbon steel systems. The analysis may identify areas that need pipe cleaning, repairs, or shorter inspection cycles; either for the same pipeline or other systems using similar pig traps.

Discover NiGen’s Pipeline Pigging Services

NiGen is a pigging service provider offering full pipeline pigging process support. Our services include the specification and supply of cleaning pigs, batching pigs, and inspection pigs for pipelines transporting natural gas, oil, or carbon dioxide. We evaluate pipeline geometry, internal diameter, flow medium, and operating pressure to determine the most effective pigging technology. Our team assists with system preparation, pig launcher and receiver operations, and integration with related activities such as nitrogen purging, hydrotesting, and drying during pipeline decommissioning or commissioning workflows.

Our technicians support pipeline operators during all phases of pigging. Applicable to natural gas, oil pipeline, and CO₂ transmission lines.

Contact us online today to learn more about our services or request a quote.

Read Now: 4 Online Resources to Help with Your Next Gas Pipeline Process