Industrial Pipeline Cleaning: Services, Equipment, and Maintenance Timing

Like any other industrial equipment, pipelines require routine maintenance to maintain optimal functionality. With exposure to both internal and external conditions, pipelines can undergo corrosive damage leading to contaminant buildup, structural damage, and product contamination. Regularly scheduled cleaning activities can be used to prolong the useful lifespan of pipelines.

Importance of Pipeline Cleaning

Maintaining industrial pipelines is critical to production operations for several reasons. To begin with, oil and gas pipelines are susceptible to wear over time, exposing them to moisture and chemical attacks. Unchecked oxidative processes will result in pipeline corrosion and the buildup of deposits within the pipeline channels. This will result in damage to the structural pipeline integrity as well as contamination of products being conveyed by the pipelines.

Regular pipeline cleaning will identify points of concern, eliminate buildup within the channels as well as inhibit negative oxidative reactions, and prolonging pipeline durability. Perhaps more importantly, routine pipeline cleaning should be an integral part of the industrial safety checklist to ensure occupational health and safety risks to personnel are as minimal as possible.

When to Implement Pipeline Cleaning

Having established the usefulness of industrial process pipeline cleaning, it is equally important to know when to implement pipeline cleaning solutions. There are various points in the lifetime of a pipeline where pipeline cleaning services must be used.

Among the critical phases of pipeline operation where cleaning should be done include:

- Pipeline pre-commissioning activities immediately after a new pipeline have been installed but before full operational use is commenced

- During pipeline commissioning (dewatering, drying, and conditioning)

- Routine operation (gas transport)

- Adoption of a new service or installation of a new component

- Conduit clearance before termination of gas transport

- Pipeline decommissioning and abandonment, recovery, or re-use in another process

The above-mentioned scenarios mandate pipeline cleaning to ensure the safety of all persons involved in the pipeline operation. Further, careful maintenance will ensure compliance with environmental safety regulations.

Pipeline Cleaning Frequency Guidelines

Cleaning intervals vary by pipeline type and service conditions:

- Natural gas pipelines carrying wet gas or condensate may need cleaning every few months to remove liquids and solids.

- Dry gas lines can operate longer between cleanings (typically once per year or based on inspection results.)

- Crude oil pipelines may require more frequent cleaning if paraffin, sludge, or water buildup is present.

Operators will use these indicators to schedule cleaning:

- Sudden or gradual pressure drop across pipeline segments

- Reduced flow rate or throughput

- Data from smart pigs showing buildup, corrosion, or wall loss

Note: All cleaning intervals should be documented and tracked as part of scheduled maintenance operations.

2 Types of Pipeline Cleaning Methods

Outlined below are six effective pipeline cleaning techniques available to industrial pipeline operators:

- Mechanical pipeline cleaning methods

- Chemical pipeline clearance methods

The various ways to achieve mechanical and chemical cleaning for oil and gas pipelines are described in the subsequent sections of this article.

Mechanical Pipeline Cleaning

Mechanical clearance of buildup within gas channels is done using pipeline cleaning pigs. Pipe cleaning pigging systems come in various configurations, including utility and gel pigs.

Gel Pigs and Swabbing

Gel pigs are a popular choice for operators in moisture and debris removal, as well as pipeline dewatering and drying processes. Gel pigs are designed for use in pipelines categorized as “unpiggable” with difficult to navigate bends and poor/absent launch and retrieval hardware.

Additional benefits of using gel pigs include:

- Improved moisture absorption

- Reduced wear with longer pig lifespan

- Higher drive efficiency

- Greater handling and elimination of solid contaminants

- Dislodgment of other mechanical pigs stuck in pipeline channel

Utility Pigs

Utility pigs are used in conventional pipe cleaning operations to achieve mechanical clearance of solid contaminants, water vapor, and debris. These pigs can also be used in pipeline proving operations to determine the nature of buildup within the affected pipelines and guide the approach to clearance. These pigs, however, require standard launch and retrieval hardware to function properly.

Examples of utility pigs include:

- Mandrel pigs

- Solid cast pigs

- Foam pigs

- Spherical pigs

Inspection and Monitoring During Cleaning

Monitoring pipeline conditions during and after cleaning helps confirm cleaning effectiveness and plan follow-up actions. During the cleaning process, operators record pressure profiles, flow rate changes, and debris volumes collected at the pig catcher. In systems using smart pigs or inspection tools, comparison of pre- and post-cleaning data helps assess the cleaning coverage.

For pipelines requiring visual confirmation, bore scopes or endoscopic tools may be inserted after cleaning runs. This is especially important when verifying the cleanliness of launch and receiver traps, or when using flushing solutions that leave residues.

Pipeline Chemical Cleaning Procedure

Pipe cleaning can also be achieved using chemical means, including purging with nitrogen gas and other specialty flushing solutions.

Nitrogen Purging

Pipeline purging with gaseous nitrogen can be used to eliminate various types of contaminants, including oxygen, corrosion particles, and moisture. Forcing a stream of nitrogen gas through the pipeline will drive out these impurities. As an added benefit, the inert nature of nitrogen will help stabilize the internal environment of the pipeline reducing the likelihood of combustive events occurring.

Specialty Solution Flushing

This technique is a combination of chemical flushing and mechanical pigging. Mixing liquid cleaning solutions with diluents like water, isopropyl alcohol, diesel, or methanol, will produce an effective pipe cleaning solution. This specialty solution can be driven by mechanical pigs through a pipeline to clear buildups of particulate impurities. When constituting the cleaning fluid, operators must consider the following:

- Effectiveness of the solution in penetrating contaminant buildups

- The neutrality of solution pH

- Safety/ease of handling

General Pipeline Cleaning Process

Regardless of the type of pipeline targeted for maintenance, there are general ways by which pipe clearance can be achieved. Some universal pipe cleaning guidelines are outlined below:

- Identify and take control of all inlet and outlet valves associated with the pipeline to be pigged

- Use valves to shut off a section of pipeline targeted for cleaning

- Measure the pressure within the pipeline by opening an operational valve

- Note directions of fluid movement and flow rate within pipeline channel

- Prove pipeline to assess nature of impurity buildup

- Apply appropriate pig sizes to clean targeted pipeline channels

- Monitor cleaning progress using line size swabs

- Flush/purge pipelines to complete the cleaning process

Pigging Equipment Overview

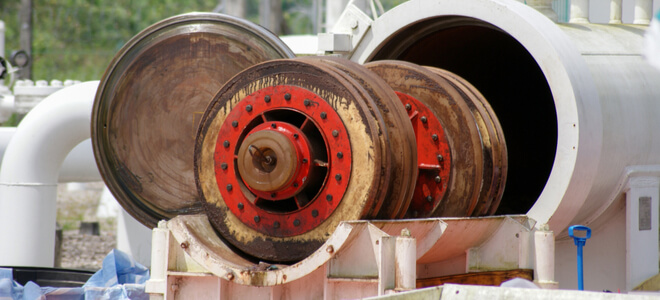

A typical pigging system includes launchers, receivers, and pigging components built for the application. The pig launcher is a pressurized chamber where cleaning pigs are inserted into the pipeline. The pig receiver, or pig catcher, is located at the end of the cleaning run and collects the pig after it has passed through the pipeline.

Additional hardware:

- Isolation valves for segment control

- Bypass piping for flow redirection

- Pig signalers for tracking pig position

- Drain and vent lines for safe depressurization

Operators must use compatible hardware based on pipeline diameter, operating pressure, and cleaning pig design. Pigging systems should match the cleaning goal: light debris removal, product batching, or pre-inspection preparation.

NiGen Has the Pipeline Management Solutions You Need

NiGen International is dedicated to providing high-quality industrial solutions to all its clients. We offer pipeline maintenance services for players in the oil & gas industry. Our pressure testing and pipeline management solutions are guaranteed to optimize your product transport processes.

Contact us online to learn more about maintaining pipeline efficiency with our industrial pipe cleaning services.