Laser Cutting with Nitrogen Gas: Air Assist, Oxidation Prevention & More

Nitrogen gas is used across many industries, including food preservation, electronics manufacturing, and oil and gas processing. Another area where nitrogen proves useful is in laser cutting operations. This article explains how nitrogen contributes to precision cutting, prevents oxidation, and improves operational output in both laser and plasma cutting.

What is Laser Cutting?

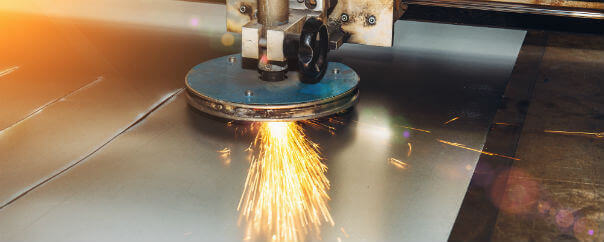

Laser cutting is an industrial fabrication process that uses a high-powered laser beam to cut materials such as carbon steel, stainless steel, titanium, and aluminum. To support this process, an assist gas is often added. The gas helps remove material, improves edge quality, and keeps contaminants away from sensitive components.

Common Gases Used in Laser Cutting

Laser cutting systems use several gases:

- Carbon dioxide (CO₂)

- Nitrogen (N₂)

- Compressed air

The gas selected depends on the material being processed, cost factors, and desired cut characteristics. Nitrogen is often chosen for stainless steel and aluminum because it does not react with hot surfaces.

CO₂ Lasers vs. Fiber Lasers

Fiber lasers are gaining popularity in the metal fabrication industry. Compared to CO₂ lasers, fiber lasers provide:

- Faster cutting speeds (up to 5x quicker)

- Lower operating costs

- Better energy efficiency

- Improved safety profile (less beam reflection)

What is Plasma Cutting?

Plasma cutting uses a jet of ionized gas combined with an electrical arc to melt and push metal away. When nitrogen is used in these systems, it produces cleaner cuts with less heat damage, especially on stainless steel and other conductive metals.

Related Blog: DOES A PLASMA CUTTER NEED AN AIR DRYER?

Why Use Nitrogen in Laser Cutting?

Nitrogen supports gas-assisted laser cutting in several ways:

1. Clean Cutting

Being inert, nitrogen does not cause oxidation. The result is clean, burr-free edges, especially when working with stainless steel and aluminum.

2. Laser Beam Purging

Directing nitrogen through the laser beam path helps remove oxygen and contaminants. This supports consistent beam quality and more uniform cuts.

3. Oxidation Prevention

Nitrogen displaces oxygen at the cut surface, which helps prevent rust and discoloration. This is helpful when parts require painting, welding, or a clean appearance.

Improved Cutting Results with Nitrogen Support

Using nitrogen or air as an assist gas offers these benefits:

- Cleaner Cut Edges: Less slag and dross buildup

- Faster Processing: Cuts through materials quicker

- Lower Costs: On-site nitrogen or ambient air reduces dependence on delivered gases

- Reduced Heat Damage: Nitrogen produces less thermal stress on metal

Can I add a nitrogen generator to my current laser cutting system?

Yes – most on-site nitrogen generators are designed for flexible installation alongside existing equipment.

Why Choose On-Site Nitrogen Generation?

For operations handling large amounts of laser cutting, on-site nitrogen generation is a practical and cost-saving solution.

A nitrogen generator for laser cutting delivers:

- Steady supply of nitrogen

- No need for cylinder storage or delivery

- Lower long-term operating costs

- High purity gas (up to 99.999%) for clean cuts

Using a nitrogen generator for laser cutting helps improve independence, reduce wait times, and simplify gas management.

Nitrogen Purity & Performance

Laser cutting systems benefit most from nitrogen with high purity levels. Impurities in assist gas can cause discoloration, spatter, or oxidation on cut surfaces. A nitrogen generator for laser cutting can consistently produce gas at purity levels required for cutting stainless steel, titanium, and aluminum parts used in consumer and industrial products.

Generator Specifications

Typical features of a nitrogen generator for laser cutting include:

- Purity: 95% to 99.999%

- Flow rates: Scalable systems from 20 SCFM to 500+ SCFM

- Pressure range: Adjustable output from 100 to 500 psi

- Modular design for easy integration into fabrication facilities

These systems are often skid-mounted for quick installation and mobility within existing production environments.

Partner with NiGen for Your Nitrogen Supply

NiGen provides nitrogen systems for many industrial cutting applications. For permanent setups or temporary use, our nitrogen generator rentals support reliable performance at a reasonable cost.

If you’re considering a nitrogen generator for laser cutting, or want more details about our nitrogen systems, contact our team today to request a quote or speak with a representative.