Nitrogen Use in Metal Fabrication and Welding: Best Practices

Whether you are engaged in welding, cutting, or both, leveraging nitrogen effectively will help you achieve superior outcomes and maintain a competitive edge in the industry.

Why Nitrogen?

Nitrogen is an inert gas, which means it does not react easily with other elements. This characteristic makes it an excellent choice for applications in metal fabrication and welding, where the prevention of oxidation and contamination is critical. Here are some primary reasons nitrogen is used:

- Oxidation Prevention: During welding and cutting processes, exposure to oxygen can lead to oxidation, resulting in weak joints and compromised structural integrity. Nitrogen acts as a protective shield, preventing oxidation.

- Improved Weld Quality: Nitrogen helps in achieving cleaner and more precise welds by minimizing spatter and providing a stable arc.

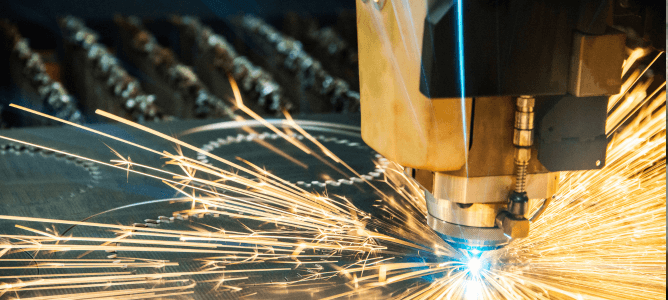

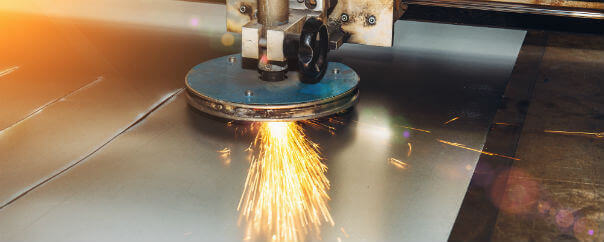

- Enhanced Cutting Performance: When used in laser cutting, nitrogen assists in achieving smoother cuts and reducing the risk of material warping.

Best Practices for Using Nitrogen in Metal Fabrication

Nitrogen plays a pivotal role in the metal fabrication and welding industry, offering numerous benefits that enhance quality and efficiency. By following best practices in nitrogen supply, regulation, safety, and equipment maintenance, you can ensure optimal results in your metalworking projects.

1. Choosing the Right Nitrogen Supply

The first step in optimizing nitrogen use is selecting the appropriate supply method. Nitrogen can be supplied in various forms, including:

- Compressed Gas Cylinders: Suitable for smaller operations or applications where portability is needed.

- Liquid Nitrogen: Ideal for high-volume usage, as it offers a more cost-effective and continuous supply.

- On-Site Nitrogen Generators: For large-scale operations, on-site nitrogen generators provide a reliable and uninterrupted supply, eliminating the need for cylinder handling and reducing costs over time.

2. Regulating Nitrogen Flow

Proper regulation of nitrogen flow is crucial for maintaining consistent quality in welding and cutting. Too much nitrogen can lead to excessive pressure, while too little can result in inadequate protection. Utilizing flow meters and regulators designed for nitrogen use ensures precise control and optimal performance.

3. Maintaining Equipment

Regular maintenance of equipment used in nitrogen applications is essential for ensuring efficiency and safety. This includes checking for leaks, inspecting hoses and fittings, and calibrating flow meters. Routine maintenance helps prevent downtime and extends the lifespan of your tools and machinery.

4. Implementing Safety Measures

Nitrogen, while beneficial, can pose safety risks if not handled properly. Implementing safety measures such as adequate ventilation, proper storage of cylinders, and training personnel on nitrogen handling protocols is vital. Always adhere to industry safety standards and guidelines to prevent accidents and ensure a safe working environment.

Best Practices for Using Nitrogen in Welding

1. Pre-Welding Preparation

Before welding, ensure the surfaces to be joined are clean and free from contaminants. Nitrogen can help in purging the weld area, removing any residual oxygen and moisture that could lead to defects.

2. Using the Correct Purge Technique

Purge welding is a technique where nitrogen is used to displace oxygen in the weld zone. This is especially important for materials like stainless steel and titanium, which are highly susceptible to oxidation. Use a purge dam or tape to create an airtight seal, and introduce nitrogen to maintain a protective atmosphere.

3. Monitoring Weld Quality

Consistent monitoring of weld quality is essential for ensuring the desired outcomes. Visual inspection, along with non-destructive testing methods such as X-ray or ultrasonic testing, can help in identifying any defects and ensuring the integrity of the welds.

Best Practices for Using Nitrogen in Cutting

1. Optimizing Cutting Parameters

When using nitrogen for laser cutting, optimizing parameters such as pressure, speed, and focal point is crucial. Adjust these settings based on the material type and thickness to achieve precise and clean cuts.

2. Ensuring Clean Surfaces

Just like in welding, clean surfaces are vital for effective cutting. Remove any coatings, oils, or debris from the material surface before cutting to enhance the efficiency and quality of the cuts.

3. Regular Maintenance of Cutting Equipment

Regularly inspect and maintain your cutting equipment, including lasers and nozzles, to ensure optimal performance. Replace worn-out components promptly to prevent any disruption in the cutting process.

Discover the Power of On-site Nitrogen Generation Systems

Transform your operations with NiGen’s on-site nitrogen generation systems. Say goodbye to the hassles of cylinder deliveries and fluctuating gas prices. Our systems provide a reliable, continuous supply of high-purity nitrogen, tailored to meet your specific needs. Experience unmatched convenience, cost savings, and efficiency.

Contact us today to learn more about our nitrogen generators for rent and sale.