Everything You Need to Know About Industrial Air Filtration

Industrial air filtration is essential for ensuring safe and clean products from industrial processes. Moreover, this process is ideal for residential applications, especially with the increased rate of allergy and asthma. This article explores the need for air cleaning in various applications and discusses some critical considerations for selecting the ideal air filtration system.

What is Industrial Air Filtration?

Air quality is a crucial factor in several industrial applications. These applications require high air quality to ensure high product integrity, minimize pollution, and ultimately maximize product safety.

Manufacturers achieve this high air quality by incorporating air filtration systems into industrial processes. Industrial air cleaning removes solid particulates and molecular contaminants from industrial processes for air quality improvements within a system or environment.

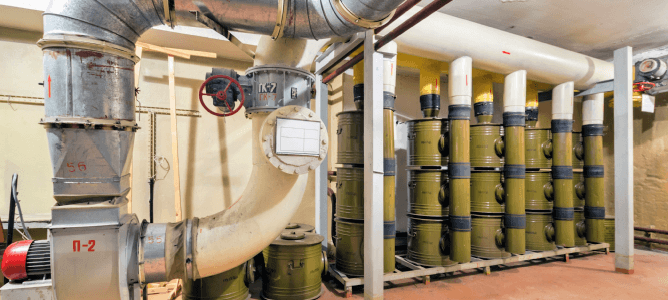

Industrial air filtration systems typically comprise a sturdy frame encasing a filter media, tightly sealed to eliminate frame-media leakages. Manufacturers ensure the production of clean and safe products by incorporating these air purification systems into air compression systems and air dryers.

How Do Industrial Air Filters Work?

The high need for clean and dry compressed air in applications, such as pharmaceuticals, research and development, defense, and food processing, has led to the increased incorporation of industrial air filters. Unfortunately, the availability of compressed air does not automatically translate to acceptable air qualities for these applications. While installing the suitable air dryer eliminates corrosion and contaminant-enabling moisture, air filters screen out accumulated debris or contaminants.

The general working principle of industrial air filters includes the flow of air from the compressor to the dryer and then to the particulate filter, which traps the debris, oil, dirt, and other contaminants. Another dryer further dehumidifies the resultant air and sends it to a coalescing filter, eliminating aerosols, oil, and water impurities, continuing to another particulate filter for final air purification.

What Industries and Applications Are Air Filtration Systems Used For?

Commercial air filtration systems are ideal for applications that benefit from air compression and air dryer systems. Some key industries that require industrial air filter systems include food and beverage processing, pharmaceuticals, petrochemicals, defense, and energy production.

Moreover, there has been an increasing need for industrial-grade air filtration systems in residential facilities due to increasing asthma and allergy rates. With these air filtration systems, customers have a high assurance of high air quality regardless of the need or application.

Things To Consider When Choosing An Air Cleaning System

A few key considerations for selecting the ideal air cleaning/filtration system in many applications include size, ease of installation and mobility, efficiency, cost and availability, and manufacturer’s brand.

Size

The ideal air filtration system for a specific application requires the customer to determine the cubic feet per minute (CFM) rating of the application. Determining this rating includes dividing the size of the space/system by the air exchange rate (AER). AER varies depending on the application.

For instance, foundry, welding, and general ambient air applications exhibit AER of up to 8, 6, and 10 minutes, respectively. Moreover, the customer can determine the size in cubic feet by multiplying the length, width, and height of the system or space.

Ease of Installation and Mobility

Customers must opt for a system that is easy to install, depending on the size and potential location of the available space and the existence of other methods, such as fans, cranes, and heat ventilation air conditioning (HVAC), within the same area. Moreover, it is essential to consider the system’s mobility due to the likelihood of business growth, change, or relocation. It would be easier to handle mobile air filtration systems than stationary ones.

Efficiency

High-efficiency air filtration is the most preferred for industrial and residential applications. However, the system must be cost-efficient and self-sustaining. A cost-efficient air filtration system strikes a balance between running and maintenance costs and performance.

Specialists recommend low horsepower rated systems to ensure minimized running costs. Similarly, a self-sustaining system offers high-efficiency air filtration during hot and cold seasons, eliminating additional heating and cooling bills from filtration systems that require outside ventilation to perform.

Cost and Availability

Customers must also consider the cost and availability of air filters and their replacements. For higher profitability, some manufacturers custom size and color their air filters. However, this can significantly increase the cost of the air filters and the difficulty of finding replacements. Thus, it is preferable to opt for filters with standard sizes and efficiencies to minimize costs during solution replacements.

Manufacturer’s Brand

The manufacturer’s brand depends on its market reputation, customer feedback, and experience in air filter production, sales, and maintenance. Since air filtration systems are crucial for industrial processes and residential and business applications, customers must prioritize their research into different brands to ascertain the one with high review and customer satisfaction.

Explore NiGen’s Line of Industrial Air Filtration Systems

NiGen is dedicated to offering reliable technological solutions to our clients across a wide range of industries. Our high-quality air filters are ideal for your commercial and industrial facilities. To learn more about our comprehensive line of air filtration units, please contact us online today.