How To Pressure Test a Gas Line | Requirements, Tips & More

Pressure testing gas lines is necessary for promoting safety and minimizing damage to industrial and commercial facilities. Licensed professionals and appropriate procedures are two key components that ensure the success of this process.

What is Pressure Testing?

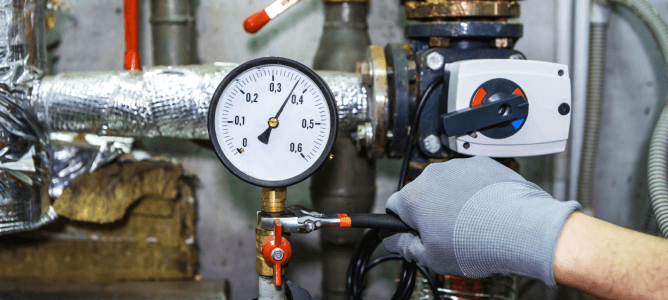

Pressure testing includes a process of ensuring the integrity of a gas line. In this process, certified professionals subject the gas line to extreme pressure to ascertain that its pipes, fittings, joints, and other essential components are in such condition that significantly eliminates the risk of gas leakages and piping system explosions.

Pressurized air, gas, or water are the key fluids professionals utilize to perform this test. The extreme amount of pressure the professional subjects the gas line to ensures that it can withstand whatever pressure and function manufacturers build it for throughout its lifetime. Additionally, the process provides the proper containment and distribution of the natural gas entering industrial and commercial facilities.

How Gas Line Pressure Testing Works

Successful gas line pressure testing significantly depends on the expertise and experience of relevant professionals: they must be familiar with the process and the various components.

Moreover, knowledge about the gas line and its maintenance is essential to the entire testing process. The process includes filling the gas line with an ideal fluid, subjecting the liquid as well as the line to extreme pressure, and verifying that the line holds the pressure over a specified period. If the line capably holds the pressure, it implies a high-integrity gas line and piping system. However, a significant drop in pressure throughout the test indicates line leakage(s) in the system, which requires identifying potential sources and appropriate repairs.

Different Pressure Testing Methods

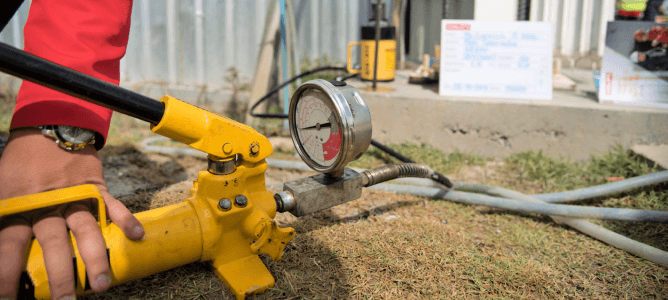

There are several methods of pressure testing gas lines for increased safety in industrial and commercial facilities. However, these methods are categorized into two standard groups: hydraulic and pneumatic.

While hydraulic pressure testing utilizes water, pneumatic leverages the capabilities of non-flammable gas for gas pipe pressure tests. Note that professionals occasionally add dye to the water during hydraulic pressure testing to ensure easy identification of leakages and other associated issues.

Hydraulic testing remains ideal for higher-pressure situations due to its relatively higher degree of safety. Conversely, pneumatic testing remains the most appropriate method for lower gas line pressure tests.

Requirements for Gas Line Pressure Tests

The existence of modern-day natural gas sniffing detectors and industry-leading detection techniques for rapidly locating and identifying leakages or defects that require correcting at high precision is assuaging fears of explosion and damage from gas lines.

However, before detecting relevant leakages, professionals must be able to ascertain their existence. Thus, the result from natural gas line pressure testing shows whether the piping in a facility can hold at least its normal operating pressure in line with some specific criteria, including the following:

- A less than 0.5 pounds per square inch gauge (psig) operating pressure-rated system must withstand a test pressure of at least 5 psig for 30 minutes.

- Systems with 0.5 to 4.9 psig operating pressure ratings must withstand up to 5 psig test pressure or 1.5 times the operating pressure, depending on the higher pressure, for 30 minutes.

- Systems operating at 5 psig and above must be able to hold pressure for at least one hour during testing.

It is recommended to either repair and retest a gas line that fails an initial test or disconnect it from the gas supply. Moreover, pressure testing requires a licensed professional, a qualified facility employee or agent, or a professional who is certified by relevant agencies.

Tips For Successful Gas Line Pressure Testing

Pressure testing a natural gas line requires a complete walkthrough of the line before the test. A quick reference to the piping schematics allows the professional to easily identify possible open ends.

The professional must also expose and evaluate all joints in the system, properly isolate parts of the system that will not be part of the test, and take complete lockout tagout measures. Other relevant tips for successful testing include:

- Verify the required test pressure and time in the area of operation.

- Bleed out system air pockets and closing vents.

- Properly calibrate gauges.

- Account for weather fluctuations by noting the system’s temperature at the test time to ensure accurate pressure measurements by placing pressure gauges at the pressure source and the farthest point.

- Meet test requirements by ensuring the system holds the stipulated pressure over the specified period.

- Promote safety by putting up safety tapes and barricades and applying pressure gradually.

- Check all connections and joints for leakages and drain pressure from the system for required repairs.

FAQs About Gas Line Pressure Testing

How often should I pressure test my gas line?

The frequency of testing depends on the type of system and usage. Industrial and commercial gas lines may require annual testing as part of routine maintenance, while residential lines typically only need testing after installation, repair, or if a leak is suspected.

How long should a pressure test last?

The duration depends on the system size and local regulations. Many tests require maintaining pressure for 15 minutes to several hours to check for leaks. Always follow the guidelines for your specific application.

What tools are necessary for a gas line pressure test?

Basic tools include a pressure gauge, air compressor or gas pump, and fittings to seal off the system. Specialized equipment may be required for larger or more complex systems.

Is pressure testing required by law?

In many jurisdictions, this testing is mandatory for new installations or after repairs. Check local codes to ensure compliance.

Can pressure testing damage the gas line?

If performed correctly within the appropriate pressure range, testing should not harm the line. Over-pressurizing the system, however, can cause damage, which is why it’s important to adhere to recommended pressures.

What are the risks of not testing a gas line?

Failing to pressure test can leave leaks undetected, increasing the risk of gas leaks, explosions, or other hazards. Regular testing ensures safety and compliance with regulations.

Do all gas lines need pressure testing?

Yes, all gas lines, regardless of material or use, should undergo testing after installation or repair to confirm their integrity and safety.

NiGen Offers Reliable Pressure Testing Services in Houston

NiGen offers clients a unique experience best suited for their natural gas pressure testing jobs. We provide industry-best pressure testing service in line with regulatory guidelines and standards in Houston. Additionally, we manufacture on-site nitrogen generators, air compressors, air dryers, aftercoolers, and booster compressors for your industrial process gas needs.

Contact us today for all your pneumatic and hydrostatic testing needs.