Stationary vs. Mobile Industrial Air Compressors: Pros & Cons

Industrial air compressors are essential across various industries, from manufacturing to construction. They power pneumatic tools, provide energy for production lines, and assist in numerous applications. When selecting an air compressor, businesses often face the choice between mobile and stationary units. Each type has its own set of advantages and disadvantages, and understanding these can help you make the best decision for your needs.

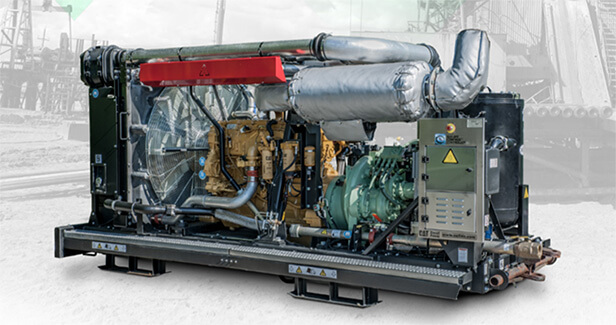

Mobile Industrial Air Compressors

A mobile industrial air compressor is a portable unit designed to provide compressed air on-site for various industrial tasks. These types of air compressors are mounted on wheels or trailers, making them easy to transport and ideal for use in construction, maintenance, and other applications where mobility and flexibility are essential.

Pros

- Portability: The primary advantage of mobile air compressors is their portability. These compressors are designed to be moved easily from one location to another, making them ideal for job sites that require frequent relocation, such as construction sites or remote projects.

- Flexibility: Mobile compressors can be used in various settings and are not limited to a single location. This flexibility allows businesses to maximize the use of a single compressor across multiple job sites, improving cost efficiency.

- Quick Setup: Mobile compressors are generally easier and quicker to set up compared to stationary units. This feature is particularly beneficial for short-term projects or emergency repairs, where time is of the essence.

Cons

- Lower Capacity: Mobile compressors typically have a lower capacity compared to stationary units. This limitation can be a drawback for operations requiring a continuous and high volume of compressed air.

- Durability Concerns: Frequent movement and transportation can lead to wear and tear, potentially reducing the lifespan of mobile compressors. Ensuring proper handling and air compressor maintenance is crucial to mitigate this issue.

- Noise and Vibration: Mobile compressors tend to generate more noise and vibration, which can be disruptive in certain work environments. Additional measures, such as noise reduction accessories or proper placement, may be required.

Stationary Industrial Air Compressors

A stationary industrial air compressor is a large, fixed unit designed to provide a consistent and reliable source of compressed air for various industrial applications.

Pros

- High Capacity and Power: Stationary air compressors are built to provide a high volume of compressed air, making them suitable for large-scale operations and continuous use. They are often more powerful and efficient than their mobile counterparts.

- Durability and Longevity: Designed for permanent installation, stationary compressors are generally more robust and durable. They can withstand continuous operation and are less prone to damage from movement or transportation.

- Reduced Noise and Vibration: Stationary compressors are often quieter and produce less vibration, contributing to a more comfortable and safer working environment. They can be housed in soundproof enclosures or installed in remote areas to further minimize disruption.

Cons

- Lack of Portability: The main disadvantage of stationary compressors is their immobility. Once installed, they are difficult to move, limiting their use to a single location. This can be a drawback for businesses with multiple job sites or changing needs.

- Higher Initial Cost: Stationary compressors often come with a higher initial cost due to their larger size, higher capacity, and more complex installation requirements. However, this investment can be offset by their efficiency and longevity.

- Installation Requirements: Installing a stationary compressor can be more complex and time-consuming, often requiring professional assistance. This process includes ensuring adequate space, ventilation, and electrical connections.

How to Choose

Choosing between a mobile and stationary industrial air compressor depends on your specific needs and operational requirements.

Mobile compressors offer flexibility and ease of use, making them ideal for temporary or remote job sites. In contrast, stationary compressors provide higher capacity, durability, and efficiency suited for large-scale or continuous operations.

So, evaluate the demands of your projects, budget, and long-term goals to make an informed decision.

Discover the Best Air Compressor Solution for Your Business

Choosing the right air compressor is crucial for the efficiency and productivity of your operations. At NiGen, we understand the unique demands of different industries and offer a wide range of industrial air compressor rentals tailored to meet your specific needs. Whether you need the flexibility of a mobile unit or the power and durability of a stationary compressor, our team of experts is here to help you make the best choice.

Contact us today to explore our solutions and find the perfect fit for you.