Air Compressor Maintenance 101: A Guide to Prolonging Lifespan

Air compressor preventive maintenance is an essential investment that safeguards operations and delivers long-term benefits, including reliability, efficiency, safety, and cost-effectiveness. So, if you’re in an industry where air quality really matters, following the rules and keeping your equipment in good shape is a must – it shows you’re serious about quality and safety.

Why Proper Air Compressor Maintenance is Important

Keeping your industrial air compressor in good condition is crucial. Preventive maintenance helps ensure it works well, lasts longer, and doesn’t break down unexpectedly. It saves you money by using less energy and preventing costly repairs. Plus, it’s better for the environment. And most importantly, it keeps your workplace safe by avoiding accidents related to neglected compressors. But where do you start?

Air Compressor Maintenance Checklist

Here is an air compressor maintenance checklist that can help keep your equipment running smoothly.

Check the oil level: Regularly check oil levels in your compressor’s pump and top it up if necessary. Replace the oil every few hundred hours of operation or according to the manufacturer’s recommendations. Read now: What type of oil does your air compressor need?

Inspect belts and pulleys: Check the belts and pulleys for wear and tear, looseness, or cracks. Tighten or replace them as necessary to keep your compressor running smoothly.

Check for air leaks: Listen for air leaks, or use a soapy solution to check connections and seals. Repair or replace leaks to prevent your compressor from overworking and losing efficiency.

Clean the air filters: Regularly clean the inlet air filters to prevent dust and debris from entering the compressor. A clogged filter will reduce airflow and increase the air compressor’s operating temperature.

Drain condensate from tanks: Water vapor can become a problem in compressed air systems, so it’s essential to drain the condensate that collects in air tanks regularly.

Schedule professional maintenance: Schedule professional maintenance and inspections with a qualified technician regularly. They can perform thorough checks to identify and fix potential problems before they become costly air compressor repairs.

Air Compressor Maintenance Schedule

Regular maintenance will prolong your air compressor’s life span and minimize the risk of breakdowns or accidents. Keep this suggested air compressor maintenance schedule handy and follow it consistently to keep your air compressor running at peak performance.

Daily:

- Check the oil level in the compressor pump. Top up if necessary.

- Inspect for any visible leaks or unusual noises.

- Drain condensate from the air receiver tank.

Weekly:

- Clean or replace the air intake filters.

- Check and tighten any loose belts or pulleys.

- Inspect hoses and connections for any signs of wear or leaks.

Monthly:

- Inspect and clean the compressor’s cooling system, including the radiator and fan.

- Check the pressure relief valve to see if it is functioning correctly.

- Lubricate any moving parts as per the manufacturer’s instructions.

Quarterly:

- Change the oil and oil filter according to the manufacturer’s recommended intervals.

- Inspect and clean the air compressor’s motor and electrical connections.

- Test and calibrate pressure gauges.

Annually:

- Schedule professional maintenance and inspection with a qualified technician.

- Replace any worn-out or damaged parts as recommended by the manufacturer.

- Conduct a thorough inspection of the entire compressed air system, including air dryers, filters, and drain traps.

NOTE: This schedule is a general guideline and may need to be adjusted based on the specific needs and usage of your air compressor. Always refer to the manufacturer’s recommendations and consult with a professional if necessary.

Questions About Air Compressor Maintenance?

When it comes to ensuring the longevity and optimal performance of your air compressor system, NiGen is your trusted partner. Our experienced technicians and engineers are dedicated to providing top-notch air compressor maintenance services. Whether you need routine check-ups, repairs, or assistance with preventive maintenance planning, we have the expertise to keep your compressed air systems running smoothly. Visit our blog for more helpful insights about industrial air compressor systems.

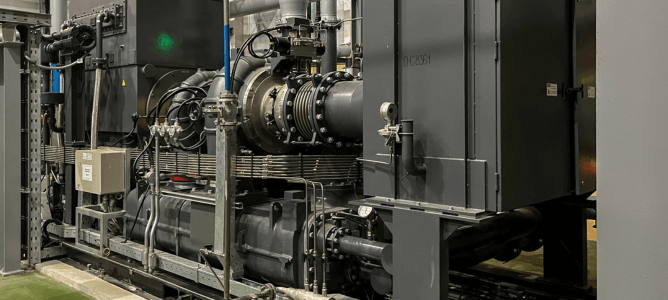

Explore NiGen’s Line of Air Compressors

At NiGen, we take pride in offering several types of air compressors designed to meet the demands of various industrial and commercial applications. Our line of air compressors is built on a foundation of reliability, efficiency, and innovation. From compact and portable models to heavy-duty industrial systems, our compressors are engineered to deliver consistent performance, energy savings, and a commitment to environmental responsibility.

Contact us today to find the ideal air compressor for your specific requirements.