Water-Cooled vs. Air-Cooled Aftercoolers

Compressed air systems power pneumatic tools, machinery, and processes in various industrial applications. However, the compression process generates heat, which can lead to moisture accumulation and other issues that can negatively impact the performance and longevity of the compressed air system. Aftercoolers are employed to reduce the compressed air temperature and remove moisture. Two types of aftercoolers often used are water-cooled and air-cooled.

What Are Aftercoolers?

Aftercoolers are heat exchangers designed to cool compressed air immediately after it leaves the compressor–their primary use is to reduce the compressed air’s temperature. By cooling compressed air, aftercoolers cause the moisture within the air to condense, making it easier to remove with downstream moisture separators and dryers. Cool air typically holds less moisture, reducing the risk of contamination and corrosion in compressed air systems and the equipment it powers.

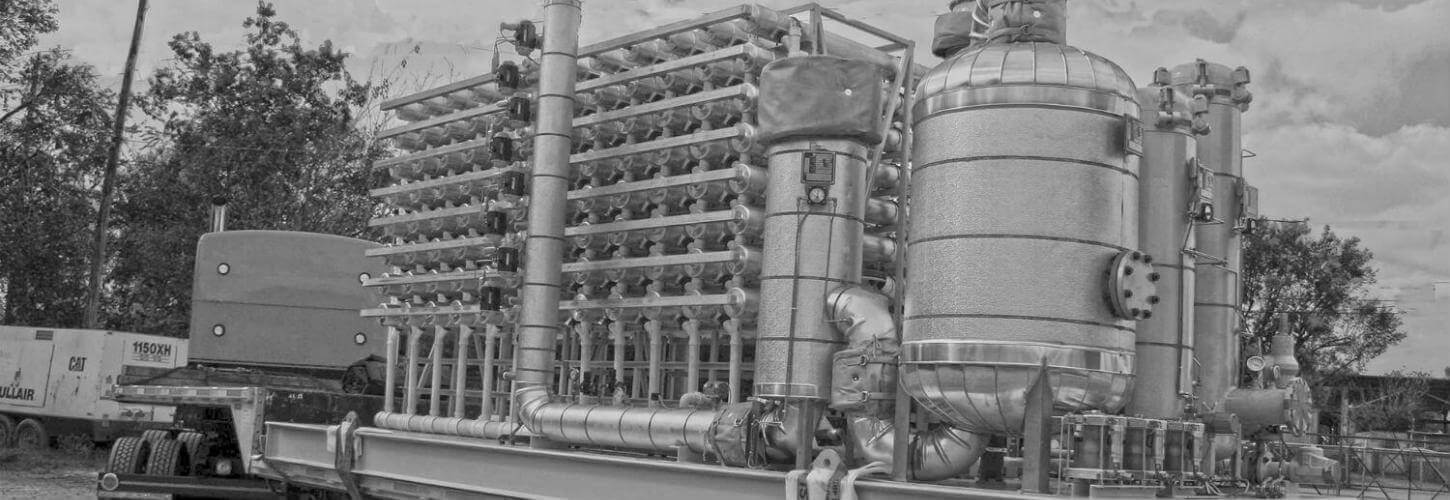

Water-Cooled Aftercoolers

A water-cooled aftercooler, also known as a shell and tube heat exchanger, uses water as the cooling medium to reduce the temperature of the compressed air. In this type of aftercooler, the compressed air passes through a series of tubes while cooling water circulates around the outside of the tubes within a shell. The heat from the compressed air is then transferred to the cooling water, effectively reducing the air temperature.

Below are some advantages of water-cooled aftercoolers:

- High cooling efficiency: Water has a higher heat capacity than air, making water-cooled aftercoolers more effective at removing heat from the compressed air.

- Compact design: Due to their high cooling efficiency, water-cooled aftercoolers can be more compact than air-cooled units, saving valuable floor space in industrial facilities.

- Consistent performance: Water-cooled aftercoolers are much less affected by ambient air temperatures, providing more consistent cooling performance throughout the year.

However, water-cooled aftercoolers also have some disadvantages:

- Higher installation and maintenance costs: Water-cooled aftercoolers utilize a reliable source of cooling water, which can increase installation and operational costs. They also require regular maintenance to prevent scaling and corrosion.

- Risk of water leakage: Water can enter the compressed air system if it leaks, leading to contamination and potential damage to downstream components and equipment.

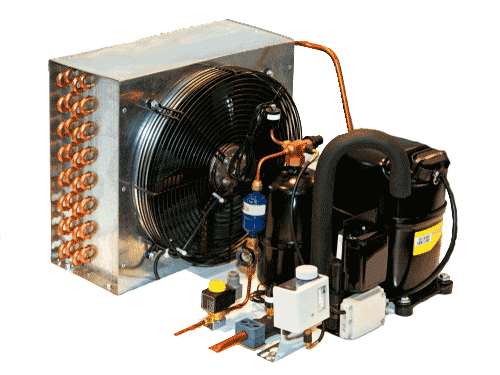

Air-Cooled Aftercoolers

An air-cooled aftercooler, also known as a fin and tube heat exchanger, uses ambient air to cool compressed air. Compressed air flows through a series of finned tubes in this type of aftercooler while a fan forces ambient air across the fins. The heat from the compressed air is transferred to the ambient air, effectively reducing the air temperature.

The following are some advantages of air-cooled aftercoolers:

- Lower installation and maintenance costs: Air-cooled aftercoolers do not require a separate cooling water system, reducing installation and operational costs. They also have fewer maintenance requirements compared to water-cooled units.

- There is no risk of contamination: Since air-cooled aftercoolers do not use water as a cooling medium, there is no risk of water leakage or contamination in the compressed air system.

- Flexibility in installation location: Air-cooled aftercoolers can be installed in a wider range of locations, as they do not require proximity to a water source.

However, air-cooled aftercoolers also have the following limitations:

- Lower cooling efficiency: Air has a lower heat capacity than water, making air-cooled aftercoolers less efficient at removing heat from the compressed air compared to water-cooled units.

- Larger footprint: To achieve the same cooling capacity as water-cooled aftercoolers, air-cooled units typically require a larger heat exchange surface area, resulting in a larger footprint.

- Performance affected by ambient conditions: The ambient temperature influences the cooling performance of air-cooled aftercoolers. In hot conditions, cooling efficiency is reduced, requiring larger or multiple units to achieve the desired cooling effect.

Factors to Consider When Choosing Between Water-cooled and Air-cooled Aftercoolers

When selecting between water-cooled and air-cooled aftercoolers for your industrial application, several factors should be considered:

- Cooling efficiency requirements: Consider the desired outlet air temperature and the cooling capacity needed for your specific application. Water-cooled types generally offer higher cooling efficiency, making them ideal for applications with stringent temperature requirements.

- Installation and maintenance costs: Evaluate the initial installation costs, including the need for a cooling water system and the ongoing maintenance costs associated with each type of system. Air-cooled aftercoolers often have low installation and maintenance costs compared to water-cooled units.

- Environmental condition: Consider your facility’s ambient air temperature and humidity levels. Air-cooled aftercoolers may be less effective in hot conditions, while water-cooled units provide more consistent performance regardless of ambient conditions.

- Contamination risks: If your application is sensitive to moisture or contaminants, consider the potential risks associated with water-cooled aftercoolers, such as water leakage or contamination. Air-cooled aftercoolers eliminate this risk by using ambient air as the cooling medium.

- System compatibility: Evaluate the aftercooler’s compatibility with existing compressed air system components, like compressors, dryers, and filters. Ensure that the selected aftercooler seamlessly integrates into your system without causing pressure drops or other performance issues.

NiGen is Your Trusted Aftercooler Supplier

When you choose NiGen as your aftercooler supplier, you benefit from our extensive industry knowledge, commitment to quality, and dedicated customer support. Our experts are ready to assist you in selecting the most suitable aftercooler for your needs, providing expert installation, maintenance, and optimization guidance.

Contact us today to learn more.