Aftercoolers vs. Intercoolers: What’s the Difference?

Many industrial processes require compressed air. Unfortunately, industrial air compressors generate significant amounts of heat that must be dissipated to prevent damage to sensitive process components.

Operators can mitigate the thermal effects of air compression by using devices like aftercoolers and intercoolers. This article covers the differences between an aftercooler and an intercooler.

Intercoolers vs. Aftercoolers for Air Compressors

The appropriate use of names for heat exchangers might prove tricky to inexperienced operators. While both intercoolers and aftercoolers are often used interchangeably, they refer to machines with subtle differences in design and operation. We clearly define how an intercooler differs from an aftercooler.

What Is an Intercooler?

An intercooler is a heat exchanger that removes heat from the air generated by an air compressor. An efficient intercooler will restore compressed air temperature to near environmental levels.

How Do Intercoolers Work?

An intercooler is usually used in turbocharged engines to cool compressed air before it enters the engine circulation. By functioning as an intake air cooling unit, an intercooler permits more air supply to the engine by increasing the air’s density, which boosts its overall efficiency and power output.

What Is an Aftercooler?

An aftercooler is a mechanical cooling unit that operates on the principles of heat exchange between two mediums — usually water and air. Aftercooler units can be used to attain temperatures between 5-20°F immediately after compressed air is released from the compression unit.

How Do Aftercoolers Work?

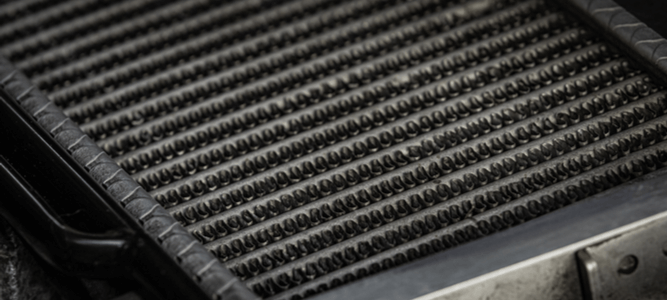

A standard aftercooler unit is composed of tubing (containing water or air) and fins that help it achieve cooling. When in operation, ambient air is pulled into the aftercooler to help remove moisture from the compressed air by condensation while reducing process temperatures to satisfactory levels. Compressed air aftercoolers are manufactured as either water or air-cooled variants.

For air-cooled compressed air aftercoolers, ambient air is directed over tubes containing hot compressed air to remove generated heat in a heat exchange process. In a water-cooled version (also called an air-to-water cooler), water is channeled through tubes running alongside compressed air pipes to achieve cooling.

What Is the Difference Between an Intercooler and an Aftercooler?

Although aftercooler and intercooler may refer to the same device and function similarly, the circumstance in which they are used provides very subtle differences. While an aftercooler is a heat exchanger that cools the air emerging from a compression unit, an intercooler is a device attached to an air compressor that cools the air before engine intake.

Advantages of Using Compressed Air Coolers

By design, both intercoolers and aftercoolers will cause the cooling of compressed air by removing the heat generated during air compression. An effect of this heat exchange is the condensation of water vapor suspended within the air, which can be collected, allowing dry air to enter supplied processes. Eliminating water will protect moisture-sensitive components and prevent equipment damage that might have arisen from moisture-enabled corrosion.

How to Choose Between an Aftercooler vs. an Intercooler for Your Application

As earlier stated, both aftercoolers and intercoolers function similarly and may be used interchangeably. Depending on the target application, either cooling device can be used to remove heat from an industrial process. However, an intercooler is advised for applications where cooled intake air is critical to engine function.

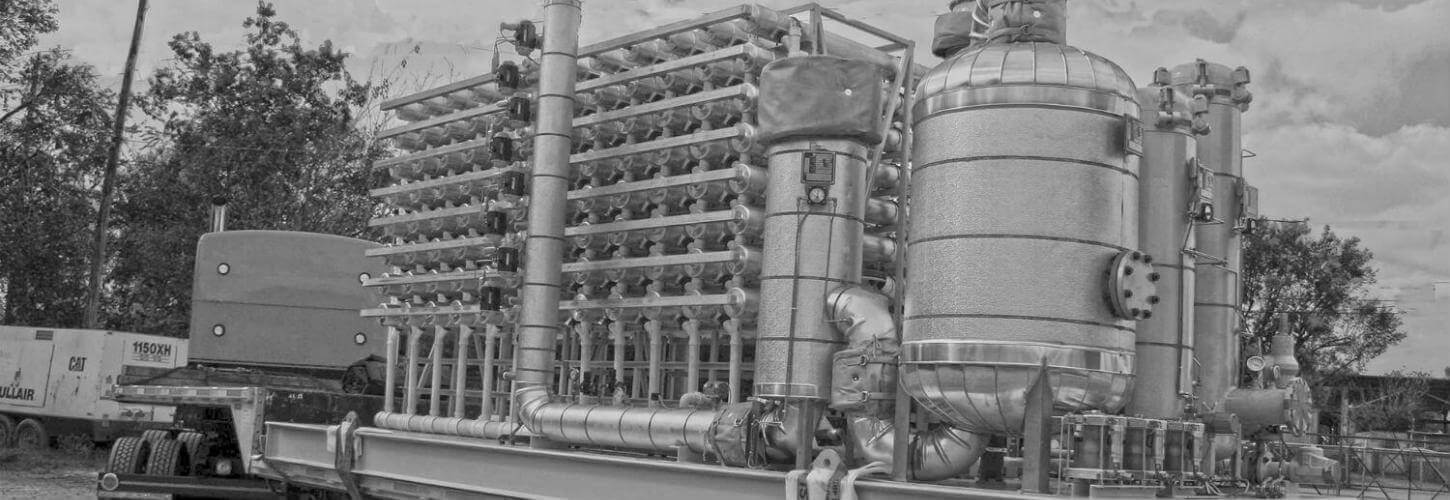

Discover NiGen’s Industrial Air Solutions Today

At NiGen, we prioritize the delivery of the best quality industrial air treatment systems to all our clients. In addition to our various compressed air solutions, we also provide air compressor aftercoolers and installation to ensure your compressed air systems meet international standards.

Contact the NiGen team today for a quote or to learn more about how we can help with your industrial air needs.