Using a Nitrogen Purging System for Transformers

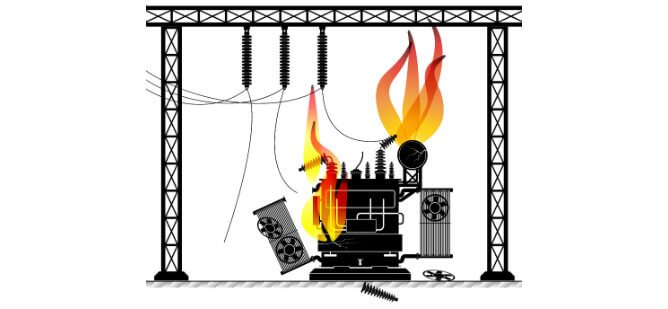

The risk of fire breakout in a power transformer may be low, but the effects could be severe if it were to occur. If an employee is working close to the transformer when an explosion occurs, the person could suffer varying degree of burns or fatal damage to vital organs.

Knowing the right precautions to take can ensure the safety of personnel and equipment at power installations. In this article, we will discuss the use of a nitrogen purging system for transformers to prevent fire hazards and widespread outages.

The Fire Triangle

To understand how a fire could occur in a transformer, it’s instructive to understand the basic requirements for fires to occur. Before any fire is started, certain conditions must be met.

A fire triangle (or combustion triangle) shows the three essential requirements which must be met for a fire to occur:

- A source of fuel

- Heat

- Oxygen

The source of fuel can be any combustible material – in the case of transformers, the cooling oil. Heat is required to ignite the fuel at its fire temperature, and oxygen provides the necessary chemical oxidative process to keep the fire burning.

Firefighting Techniques Based on the Fire Triangle Model

A basic principle of firefighting is that eliminating or reducing any elements of the fire triangle to a sufficient degree will put out a fire.

Removing the Fuel

Removing the source of fuel (also known as starvation) is one way to douse a fire. For example, an essential step in fighting an electric fire would be to isolate all sources of energy. However, it may not always be possible to remove the source of fuel due to safety concerns, particularly in fires that proliferate rapidly.

Reducing the Heat

Heat reduction lowers the temperature of the burning media sufficiently to extinguish the fire. Water is an effective substance for rapid cooling of fires that burn with combustible organic and inorganic substances such as wood and petrol. However, it is unsuitable for putting out electric fires due to the risk of electrocution.

Reducing the Oxygen

Reducing the oxygen level at the point of a fire is one of the most effective ways to put it out. Oxygen displacement using carbon dioxide (CO2) fire extinguishers is one of the common firefighting techniques. The main downside, however, is in the response time to an incident.

Since fire extinguishers are human-operated, they pose significant safety implications which may include slow response (by the human) to an incident or incorrect operation. A Transformer Explosion Prevention and Fire Extinguishing System, on the other hand, can provide automated safety at power installations.

What Causes a Transformer Fire?

Most transformer fires occur following a rupture of the main oil tank or conservator tank due to short circuit conditions which create an explosive air-oil mixture. The main tank usually contains low-viscosity oil with good dielectric properties which functions as a cooling medium for the windings and keeps the internal components free from dust and moisture. In transformers rated up to 50kV, the main tank is completely filled with oil.

If an explosion were to occur, the high-pressure conditions inside the tank could send large amounts of hot liquid flying at high speeds several yards from the installation. Personnel working close to the installation may suffer from varying degrees of burns (which may or may not be fatal) and the transformer oil spill could have adverse effects on the immediate environment.

Fire Prevention System for Transformers

A nitrogen firefighting system for power transformers uses nitrogen gas to displace oxygen from the fire source, consequently subduing the necessary components of a fire. Due to its inert and lightweight physical properties (both lighter and less dense than air), Nitrogen gas is an excellent choice for use in nitrogen purging system for transformers. Moreover, nitrogen is an eco-friendly gas, unlike CO2 which is known to cause greenhouse emissions.

A Nitrogen Injection Fire Prevention System (NIFPS) is a dual-action fire safety system that uses a series of electromechanical signals to actuate valves that open to drain oil out of the transformer tank in the event of a rupture and simultaneously injects nitrogen gas into the tank to displace oxygen.

To put out the fire in a transformer, were it to occur, we can reduce the oxygen level by displacing it with nitrogen gas. The typical design consists of two systems – an explosion prevention system and a fire extinguisher system.

The explosion prevention consists of a Buchholz (surge) relay and a master relay in parallel with a pressure relief (oil drain) valve. The fire extinguisher system consists of a fire detection device, a Buchholz relay in parallel with a pressure relief valve, and a master relay.

The nitrogen gas for injection is stored in a cylinder having a pressure regulator and safety valve as well as an electric manometer to monitor the injection pressure.

A nitrogen filled transformer will have an oxygen level that is insufficient to kindle a fire. The nitrogen pressure in the transformer also helps to reduce the top oil pressure and temperature which is critical for preventing an explosion.

Looking for Reliable On-site Nitrogen Generation Systems? Think NiGen!

At NiGen, we specialize in the design and fabrication of reliable on-site nitrogen generation units. Since 1999, we have provided a robust range of turnkey nitrogen generator rentals, maintenance, and pipeline maintenance services to several oilfield and industrial operators internationally.

Contact us today for more information!