What Is a Coalescing Filter & How Does It Work?

The presence of water vapor, sulfur, ethane, methane, carbon dioxide (CO2), and other impurities in industrial process fluids and products necessitates precision filtration systems for quality control of the final products. A coalescer is an industrial device used for this purpose.

What Is a Coalescing Filter?

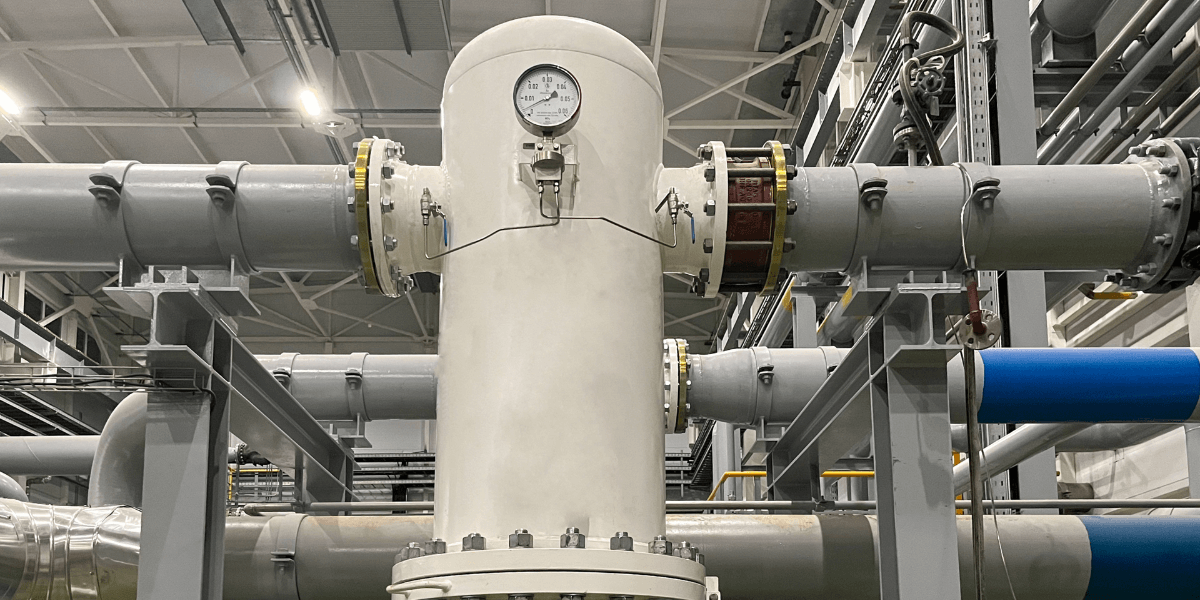

A coalescer or coalescing filter is a device used to separate fluid mixtures into individuals utilizing the principle of coalescence. Coalescence is a process whereby fluid molecules agglomerate (come together) to form a larger whole. Coalescing filters can separate particulate components of mixtures at comparable efficiencies as particulate filters.

What Does a Coalescing Filter Do?

Coalescence can separate the components of homogenous or heterogeneous mixtures and emulsions. Coalescing filters are employed in various industries, such as oil & gas and chemical plants.

Common types include the gas coalescer, oil coalescer, fuel coalescer, and condensate coalescer, which can be used for water-gas, gas-oil, and fuel-gas separation.

How Does a Coalescer Work?

A coalescing filter (or simply coalescer) is a filtration system consisting of several baffle walls or screens. A stream of fluid to be separated (e.g., a gas-water mixture) is applied to the filter, and the baffles screen out the various components by trapping them in different sections. Thus, the components of interest can be recovered in pure form while the contaminants are drained away for purification or disposal.

The screening mechanism works based on the physical properties of the component substances, e.g., molecular weight and density. In water-oil separation, the baffle walls in the coalescing filter divert the heavier oil molecules in one direction to a drain point. Meanwhile, the water vapor molecules diffuse through the filter element to coalesce and be drained out of the system gravitationally.

Similarly, in gas-water separation, ‘wet gas’ (gas stream containing water droplets) is fed into the coalescer inlet, diffuses through the filter element, and exits via an outlet port as dehydrated gas. The denser water molecules coalesce and fall to the bottom of the tank for drainage.

The Benefits of Coalescing Filtration in Industrial Processes

Coalescing filtration is an essential process in many industrial settings. It has the potential to improve the efficiency of production processes, reduce costs, and improve product quality.

Removal of Oil, Water, and Particles from Compressed Air Systems

Coalescing filtration is a process that is widely used in industrial settings to remove oil, water, and particles from compressed air systems. Coalescing filters work by trapping and eliminating submicron-sized liquid oil, water droplets, and solid particulate matter.

These filters are essential in maintaining the quality of compressed air systems, as they ensure that the air is free from contaminants that can cause damage to equipment and compromise product quality. Coalescing filters are particularly effective in removing oil and water droplets from the air, which can cause corrosion and damage to equipment.

Increased Efficiency and Longevity of Equipment

Using coalescing filtration in industrial processes can also lead to increased efficiency and longevity of equipment. In addition, coalescing filters protect equipment from damage caused by contaminants, resulting in longer equipment life and reduced downtime for maintenance and repairs.

In addition, removing contaminants from compressed air systems can result in increased efficiency, as the equipment can operate at peak performance levels without the interference of contaminants.

Improved Product Quality and Reduced Maintenance Costs

Improved product quality and reduced maintenance costs are additional benefits of coalescing filtration. In addition, coalescing filters are effective in removing contaminants that can compromise product quality, such as oil and water droplets. This can result in reduced warranty costs and improved system performance, increasing business profitability.

Furthermore, coalescing filters can reduce maintenance costs by minimizing the need for upkeep and equipment cleaning. Proper quality control and filtration are essential in ensuring that products meet all requirements and that operating costs remain low.

Additionally, microfiltration using coalescers ensures product purity of up to 95%. In addition, it is eco-friendly and consumes much less power than other industrial filtration methods.

Electrostatic & Mechanical Coalescers

There are two main types of coalescing systems based on the mode of operation.

Electrostatic Coalescers

Induces droplet coalescence in fluid mixtures using an AC or DC current, or both. Electrostatic coalescers pass an electric charge through the fluid, destabilizing the emulsion and increasing the molecules’ size, causing them to fall into the collection tank for drainage.

Typically, AC currents in the 50-60 Hz range are used for this purpose. The generated electric field causes forces of attraction between the fluid molecules causing them to come together to form heavier molecules. Electrostatic coalescers are widely used for separating water-fuel emulsions in offshore oil and gas production facilities.

Mechanical Coalescers

Do not utilize electrostatic charges; rather, employ a series of filter elements or barriers for separation. Mechanical coalescers can be used in oil refineries to separate water vapor from hydrocarbon condensate by coalescing the water molecules into larger particles which are then drained out of the system.

The purity of the final products post-separation depends on the filter element’s selectivity. Common materials used for manufacturing filter elements are borosilicate microfibers and membrane technology.

Industrial Applications

Coalescers are employed for various applications in the oil and gas and chemical industries.

Downstream Operations

In downstream oil and gas, coalescers are used for product refining. For example, at natural gas refineries, filter elements can be used to de-humify natural gas to ensure product purity before marketing.

Gas-oil coalescer systems can purify natural gas by removing several natural liquids and condensates. Furthermore, coalescing filters actively prevent corrosion in oil and gas downstream assets such as compressors, amine/glycol absorbers, turbines, and membrane filtration systems by removing contaminants such as water vapor and sulfur with efficiencies up to 99.98%.

Coalescing filters can recover lube oil from a compressor when installed at its outlet. Fluids fed into the compressor inlet may include aerosols, particulate matter, dissolved hydrocarbon liquids, and slugs and are extracted by a filter element located upstream of the compressor.

Petrochemical Industries

Liquid-liquid coalescers can be used for phase removal of water vapor, amine solutions, and sulfur from petrochemical feedstock before storage. Removal of contaminants ensures product purity and prevents corrosion of industrial equipment.

NiGen Offers On-site Nitrogen Generators & Pipeline Maintenance Services

NiGen is a world-class manufacturer of on-site nitrogen generation skids to suit the most demanding industrial applications. We offer nitrogen generator rentals to oil and gas operators and chemical industries worldwide. Additionally, we are a pipeline maintenance company providing maintenance services to the industry for nitrogen pipeline purging.

For more information or to request a quote, contact us online today or at 713-352-7169 to speak with an experienced engineer.