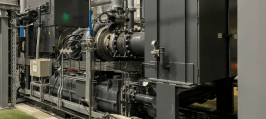

Air Compressor Maintenance 101: A Guide to Prolonging Lifespan

Air compressor preventive maintenance is an essential investment that safeguards operations and delivers long-term benefits, including reliability, efficiency, safety, and cost-effectiveness. So, if you’re in an industry where air quality really matters, following the rules and keeping your equipment in good shape is a must – it shows you’re serious about quality and safety. Why […]