How On-site Nitrogen Generation Works – PSA vs. Membrane Technology

Before on-site nitrogen generation takes place, the gas must be sourced and transported via cylinders and tanks to sites for varying industrial applications. This process can be very tedious and problematic. As a result, operators opt for one of the two technologies available for adequate on-site nitrogen generation. This article explores how nitrogen generators work in addition to their various benefits, helping you discover which system is best suited for your goals.

How Does On-site Nitrogen Generation Work?

Approximately 78% nitrogen, 21% oxygen, and a negligible percentage of other gases make up the air we breathe. Industry operators have discovered ways to take advantage of this higher nitrogen percentage to generate it for several applications on the go.

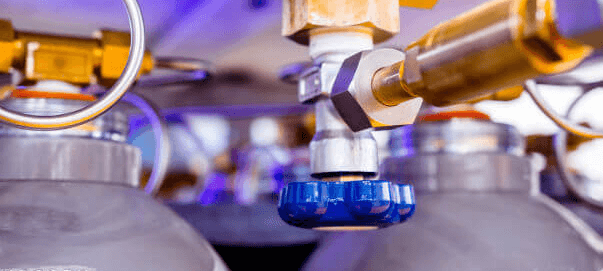

On-site nitrogen gas generation involves the separation of nitrogen gas from other air components. It ensures a dependable and cost-effective nitrogen gas supply for laser cutting, chemical blanketing, food packaging, and a host of other industrial applications.

Whatever your needs may be, on-site nitrogen generation units are preferable and more beneficial than the conventional nitrogen supply method: purchasing from vendors and transporting them to the site via cylinders and tanks. They depend on either membrane or pressure swing adsorption (PSA) technology to attain high purity levels suitable for any application. The succeeding sections reveal the differences between these two technologies while giving a closer look at why nitrogen generator installation could be your best option for nitrogen supply.

Contact our team today to get a quote on our nitrogen rental systems.

Membrane vs. Pressure Swing Adsorption Technology: What Is The Difference?

Membrane and Pressure Swing Adsorption (PSA) technologies are two methods for generating nitrogen in industrial or commercial applications. The choice between the two technologies depends on the required purity of the gas and the specific needs of your business. Membrane technology is ideal for low-purity applications, while PSA technology can produce higher-purity nitrogen. Both technologies offer cost-effective and reliable solutions for nitrogen generation in various industries.

What is a Membrane Nitrogen Generator?

A membrane nitrogen generator uses a semipermeable membrane to separate nitrogen from other gasses in the air. It is commonly used for low-flow and purity applications, such as food packaging or electronics manufacturing.

The separation membrane is the most crucial part of the nitrogen membrane system. It comprises thousands of hollow fibers through which compressed air passes to ensure highly efficient nitrogen production. Oxygen, CO2, and other gases pass through the hollow fibers more easily than nitrogen gas. These gases are then released into the atmosphere, leaving a very pure nitrogen gas stream at the membrane outlet. Operators achieve high levels of purity by simply varying the flow rate and pressure of the dry compressed air.

Hollow Fiber Membrane Systems Benefits

The major benefits of utilizing hollow fiber membrane systems for on-site nitrogen generation include:

- Its easy application in confined spaces due to its mountable nature.

- Production of high-quality nitrogen gas with a high purity range of 95 to 99.9%.

- Its compact and noiseless operation allows for greener nitrogen production and supply.

- Low maintenance requirements due to its few moving parts.

- High durability and reliability levels due to limited maintenance requirements.

What is a PSA Nitrogen Generator?

PSA nitrogen generators use a process called pressure swing adsorption to separate nitrogen from other gasses in the air. This method involves passing compressed air through a bed of adsorbent material, which traps oxygen, water vapor, and other impurities. Once the impurities have been removed, pure nitrogen gas is released from the adsorbent material and collected for use. This process is highly efficient and cost-effective, making PSA nitrogen generators a popular choice for industrial applications where high-purity nitrogen is required.

PSA nitrogen gas generator effectively separates nitrogen from the air stream. It safely, reliably, and cost-effectively achieves this with the aid of Carbon Molecular Sieves (CMS).

Using PSA nitrogen generators, operators pack two vessels full of CMS that can adsorb oxygen molecules from the compressed air that passes through them. While one is adsorbing, the other is depressurizing, allowing the downward flow of small amounts of nitrogen to release the adsorbed oxygen. This continuous process ensures that the two vessels alternate between adsorption and depressurization to produce nitrogen with up to a 99.9995% purity level.

PSA Systems Benefits

Some key benefits of PSA systems for nitrogen generation include:

- High nitrogen purity levels up to 99.9995%

- Highly reliable nitrogen generation system

- Low maintenance levels due to clean and dry compressed air feed

- Highly consistent as it produces an extensive amount of nitrogen gas

Benefits of Purchasing an On-site System from NiGen

NiGen nitrogen systems offer the highest quality standards for on-site nitrogen generation. Here are some of the top benefits of procuring these systems.

- Cost-efficient

- Saves time

- Very safe and dependable

- Greener nitrogen supply

Cost-Efficient

Sourcing nitrogen from vendors consumes more funds than an on-site generator. Some of the extra costs it incurs include transportation, storage, and costs from product loss in transit. Fortunately, NiGen offers cost-efficient on-site nitrogen systems for purchase and rent.

Saves Time

Operators can experience downtime in critical operations because of logistics-related challenges. However, with NiGen nitrogen systems, you are assured of a regular nitrogen supply for various processes.

Safe and Dependable

Nitrogen cylinders or tank leakages are poisonous to humans. However, they can be avoided by employing NiGen on-site nitrogen generators since they drastically reduce the need for pressurized nitrogen containers.

You should also note that NiGen’s on-site gas systems are ASME-certified, assuring you of dependable and safe operations.

Greener Nitrogen Supply

NiGen offers an environmentally friendly nitrogen supply by integrating other systems like desiccant dryers that prevent various forms of air contamination.

Additionally, NiGen systems are known for high offshore application ratings, revolutionary programmable logic controllers (PLCs), seamless automatic-manual switches, state-of-the-art remote monitoring, effective dew point monitoring, and low and multi-voltage systems. Their safe and dependable systems ensure a constant nitrogen supply for cost-effective project completion.

Which Nitrogen Generation System is Right for You?

When it comes to selecting a nitrogen generation system, it’s important to consider your application-specific needs before making a decision. Both membrane and PSA systems are effective in their own right, but the right choice for you will depend on factors such as purity requirements, flow rate, and cost-effectiveness.

Membrane systems tend to be better suited for low-flow and purity applications like food packaging or electronics manufacturing, while PSA systems are ideal for high-flow rates and high-purity applications, such as chemical processing or oil and gas production. By evaluating these factors, you can determine which nitrogen generation system is best for your business.

Contact NiGen for Highly Efficient On-site Nitrogen Generation

With 20+ years of experience in nitrogen generation for diverse industries, NiGen is your one-stop shop for on-site nitrogen generation systems. From portable containerized systems to skid-mounted stationary systems, standard or custom engineered available for sale or rent, we have the system to meet your specific needs or requirements.

Contact us today to learn more about our innovative solutions can power your growth.