A Quick Guide to Nitrogen Generators for LC/MS Applications

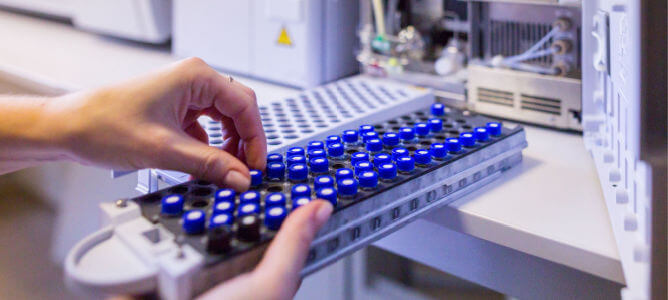

Many laboratories use liquid chromatography-mass spectrometry (LC/MS) to identify and quantify compounds in complex mixtures. However, the accuracy and sensitivity of LC/MS measurements are dependent on the purity of the nitrogen gas used as a nebulizer gas and drying gas.

Nitrogen generators provide a convenient and cost-effective solution by continuously supplying nitrogen gas that meets the stringent requirements of LC/MS applications. This article provides a concise guide to nitrogen generators for LC/MS, including their principles of operation, types, and advantages.

What Is Nitrogen Used for In Liquid Chromatography-Mass Spectrometry?

Nitrogen is an essential element that serves as a nebulizing gas and drying gas in LC/MS. It is used during the removal of sample solvents to eliminate the solvents and prevent them from reaching LC/MS components and altering the assay quality.

The purity and flow rate of the nitrogen gas used in LC/MS are critical factors that can influence the analysis’s accuracy, sensitivity, and reproducibility.

Mass Spectrometry Ionization Methods Involving Nitrogen

Nitrogen can be used in three different ways in an LC/MS, including:

Electrospray Ionization (ESI) Detectors

In electrospray ionization detectors, nitrogen is used as a nebulized gas to create a mist of charged droplets. The gaseous nitrogen aids in the separation of solvents from ionized samples prior to passage through the quadrupole onto the detector.

Atmospheric Pressure Ionization (API) Detectors

In atmospheric pressure ionization detectors, a jet of nitrogen is used to spray the samples onto the heater unit before ionization begins.

Curtain Gas

In some LC/MS applications, nitrogen also serves as a separation medium to split up samples and their solvent atoms. This is particularly important as it ensures that solvents do not enter the vacuum chamber of the mass spectrometry unit.

Nitrogen Purity Levels Required for LC/MS

When using an industrial nitrogen generator for LC/MS, the operating pressure of the generator determines the purity level. Purity is important to prevent the samples from getting contaminated.

Impurities in the nitrogen gas, such as oxygen, moisture, and hydrocarbons, can cause interference in the ionization process, leading to reduced sensitivity. In most LC/MS systems, nitrogen concentrations of 99.5% supplied at 67 L/min are sufficient.

Advantages of On-Site Nitrogen Generators for LC/MS

Using onsite-nitrogen generators for LC/MS is one of the best choices operators can make to improve the analytical process. Nitrogen generators offer many benefits, such as:

Enhanced Operational Safety

Using an on-site nitrogen generator helps businesses avoid the risks associated with handling and storing nitrogen cylinders. When using nitrogen cylinders, there is always a risk of accidental leaks occurring from faulty storage units or gas tubing. With a nitrogen generator, only the specific amount of nitrogen that is required is produced. This ensures that workers are shielded from the harmful effects of nitrogen leaks.

Convenience

Using a nitrogen generator for mass spectrometry and liquid chromatography can also make the procedure more convenient. You don’t have to worry about refilling and transporting storage cylinders, as the generator produces the nitrogen required on-site. Furthermore, using an on-site generator frees up room for movement as the floor space won’t have to be allocated to the storage of the gas cylinders.

Cheaper Running Cost

After the initial cost of installing an on-site nitrogen generator, the running cost is much lower than the price for a continuous supply of filled nitrogen cylinders. In addition to the costs of delivery and ongoing maintenance and safety checks, the replacement and recalibration of nitrogen cylinders can increase equipment downtime. You can avoid all these issues when using nitrogen generators.

On-site Nitrogen vs. Cylinders for LC/MS Laboratories

Cylinders are a traditional method of supplying nitrogen gas to laboratories. Nitrogen gas cylinders are available in various sizes, and you can rent or purchase them from gas suppliers.

However, the supply of nitrogen gas from cylinders comes with many disadvantages, such as high costs associated with transportation, rental, and disposal. Furthermore, the purity of the gas can vary depending on the supplier.

With a nitrogen generator, you can produce nitrogen gas on-site, eliminating the need for cylinder delivery, rental, and disposal. A nitrogen generator also ensures consistency in the purity of the gas compared to relying on cylinder supplies.

NiGen Manufactures LC/MS Nitrogen Generators

NiGen offers a range of high-quality nitrogen generators for LC/MS applications. Our generators are capable of producing high-purity nitrogen gas on-site, eliminating the need for costly and unreliable cylinder deliveries. Contact us today to get dependable nitrogen generators for LC/MS operations.